Market-leading. Globally proven.

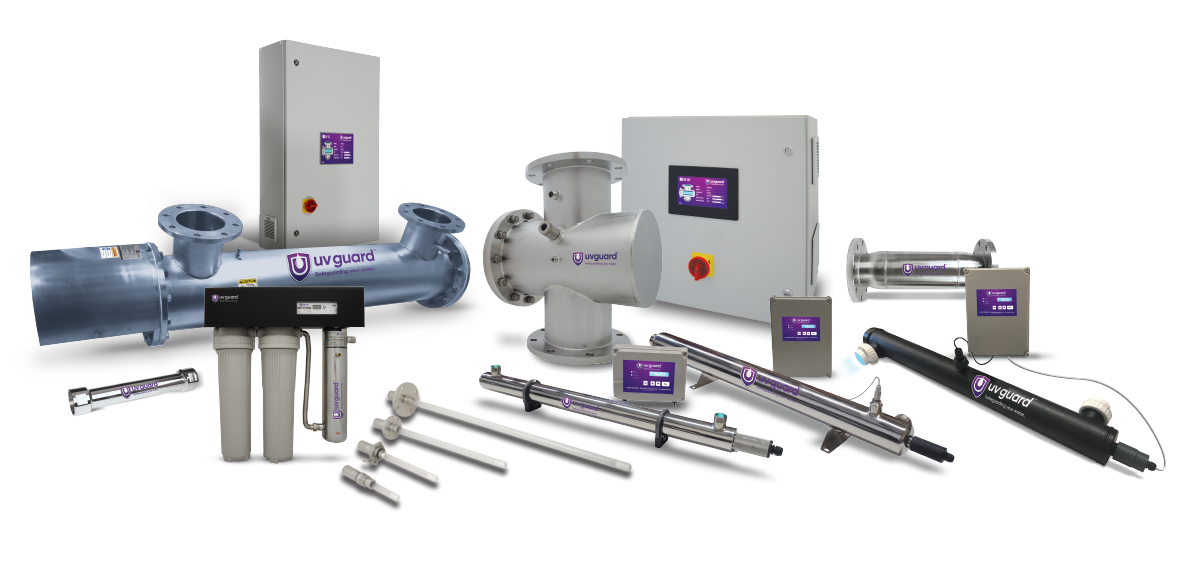

Since 2008, UV Guard has been developing, distributing and servicing some of the world’s most innovative and trusted UV disinfection systems.

Commercial Water Treatment – The Complete Guide

Your business is a complex machine where every cog and wheel play a crucial role- figuratively and literally! Untreated water can be the grit that grinds your operations to a halt.

From smaller businesses like cafes and gyms to bigger operations such as agricultural facilities and manufacturing plants, reliable water treatment is non-negotiable.

This guide will show you the best commercial water treatment solutions because your business deserves the best.

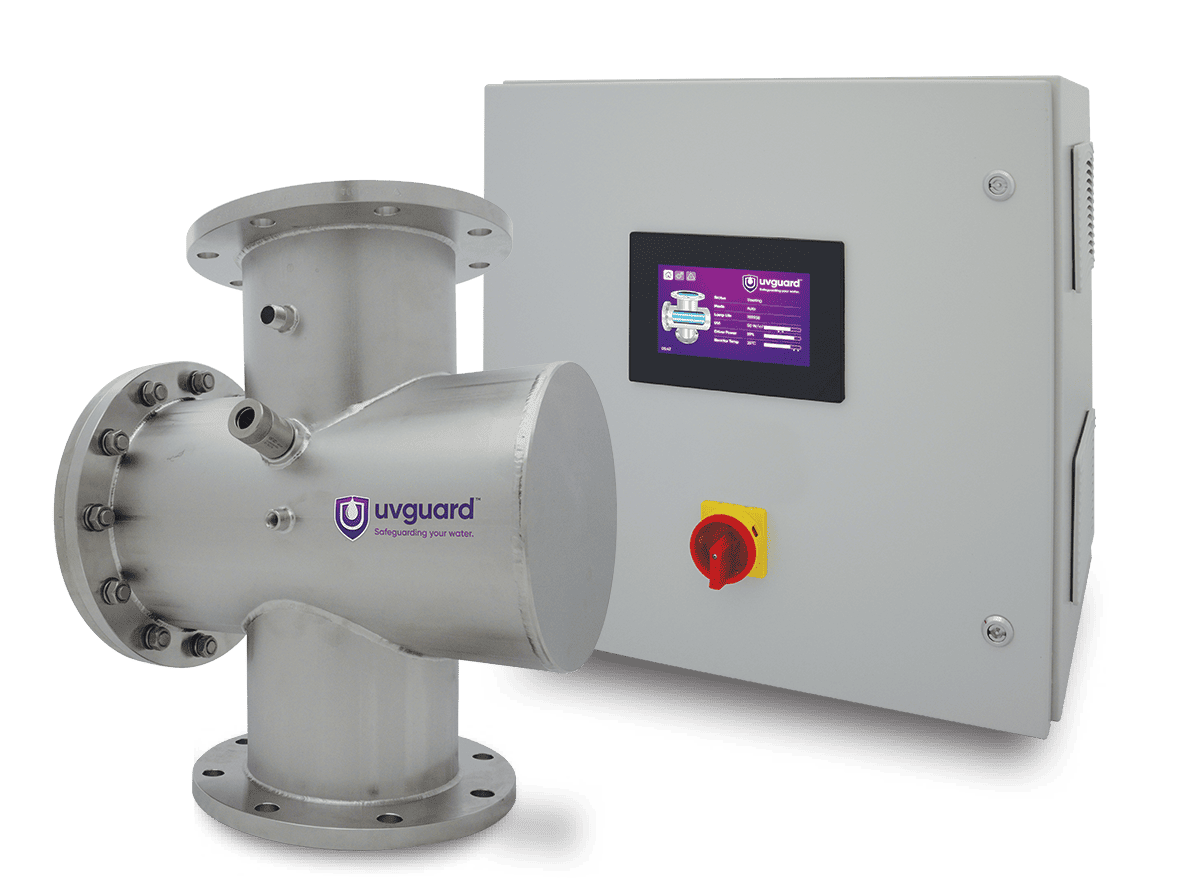

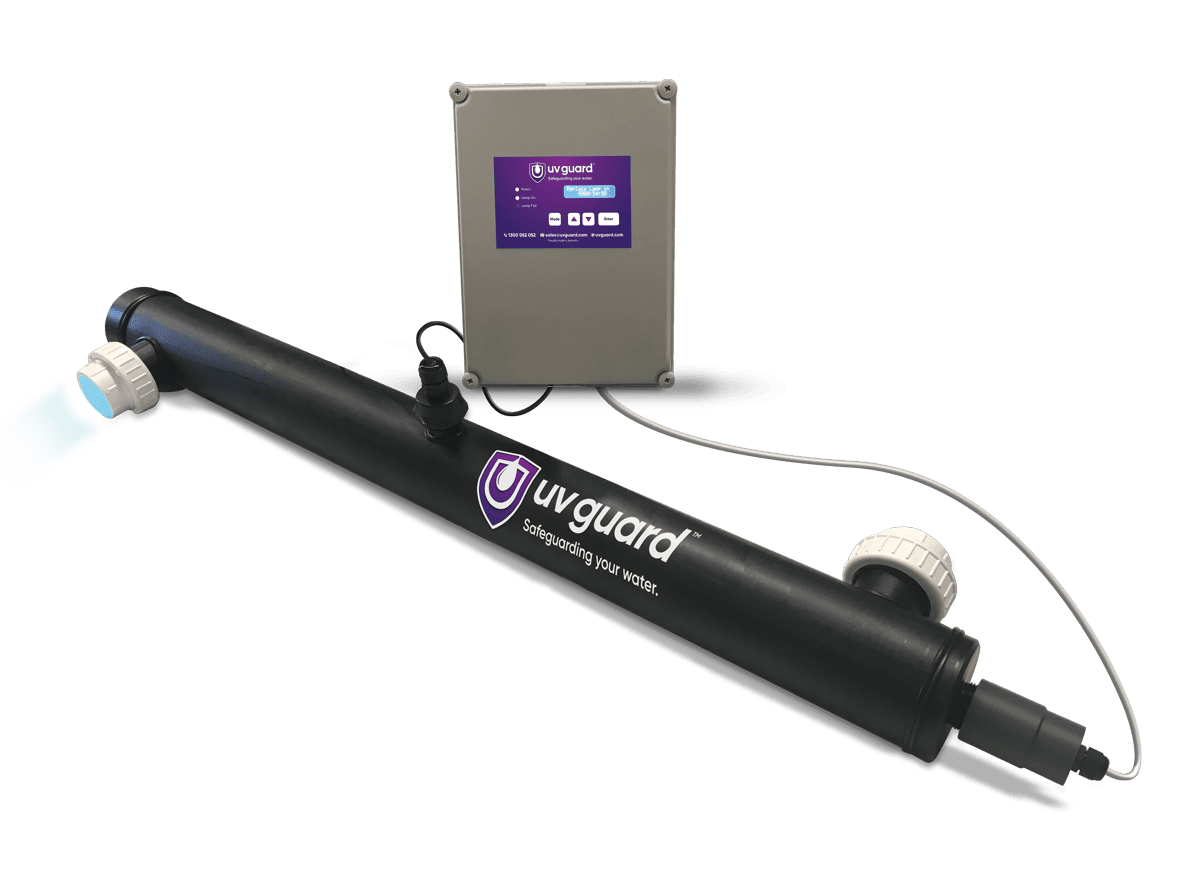

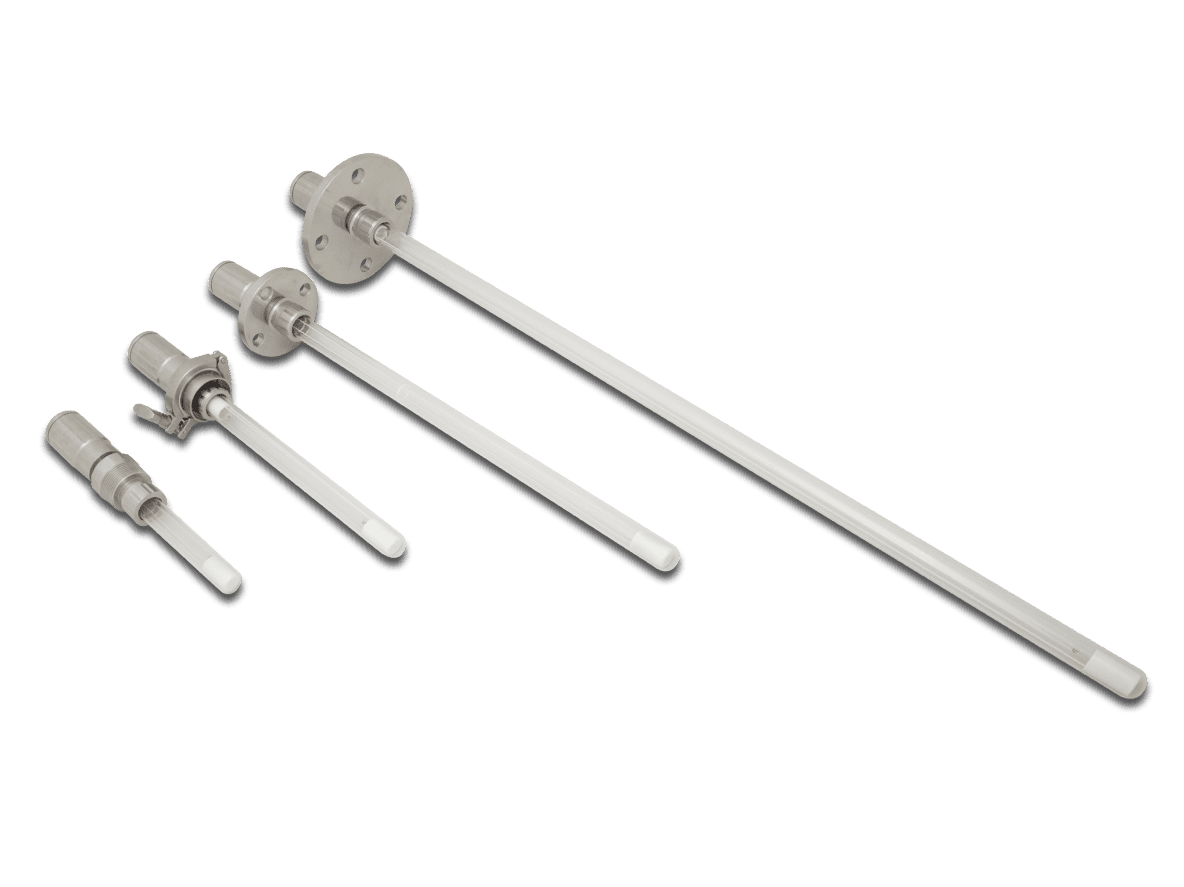

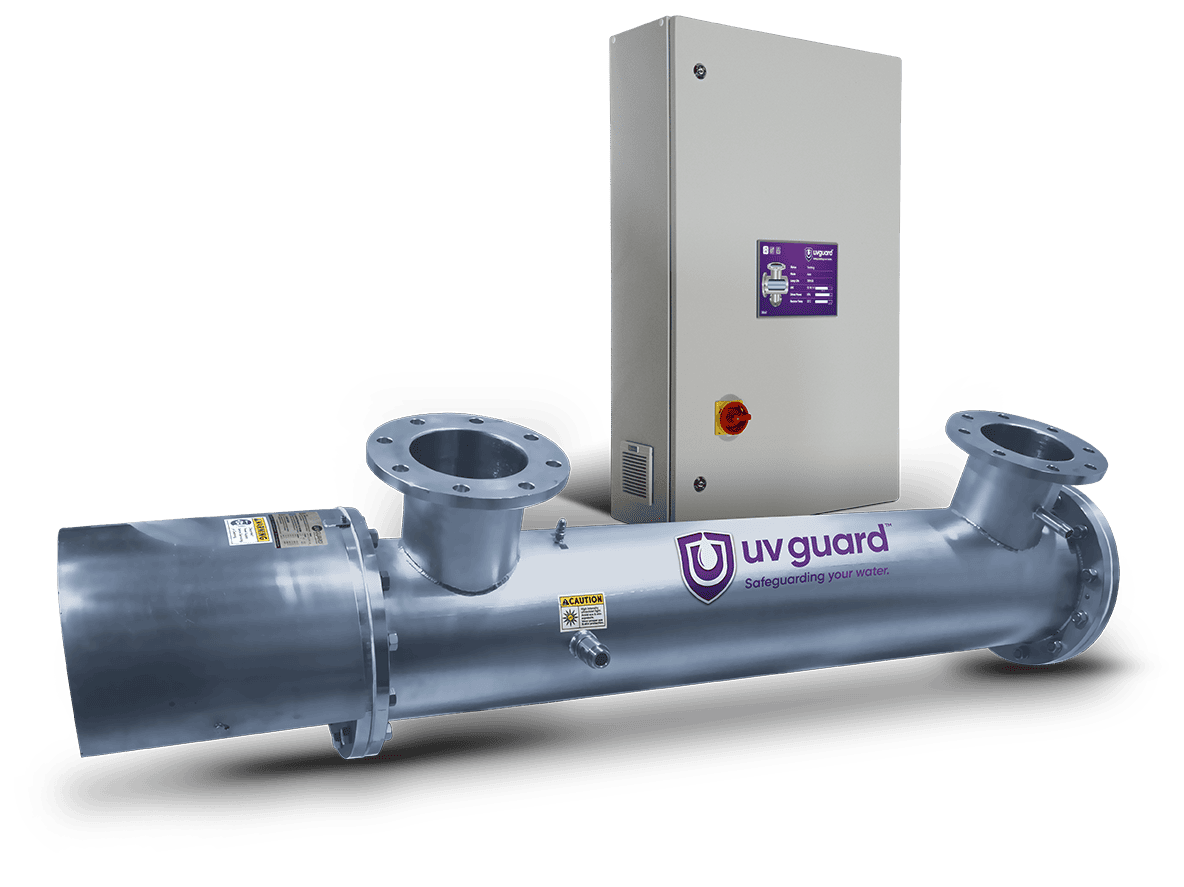

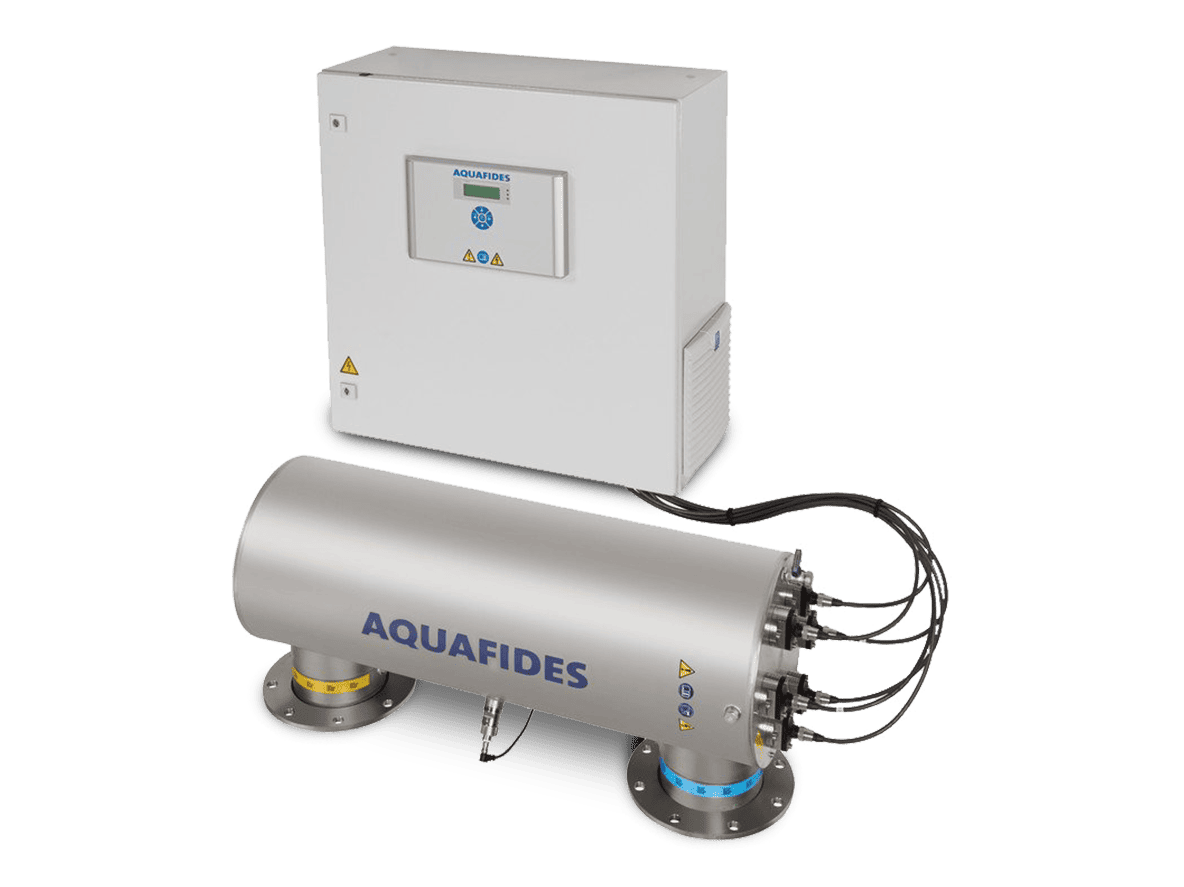

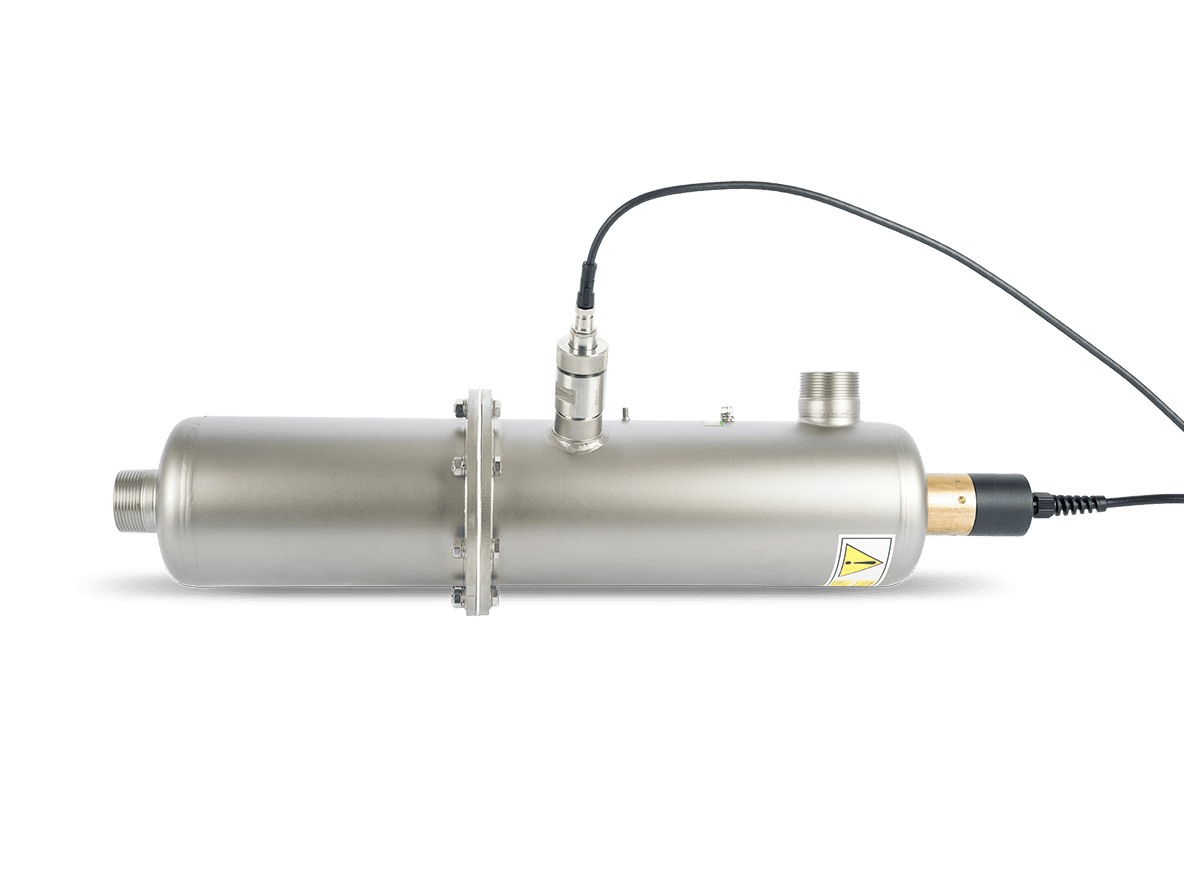

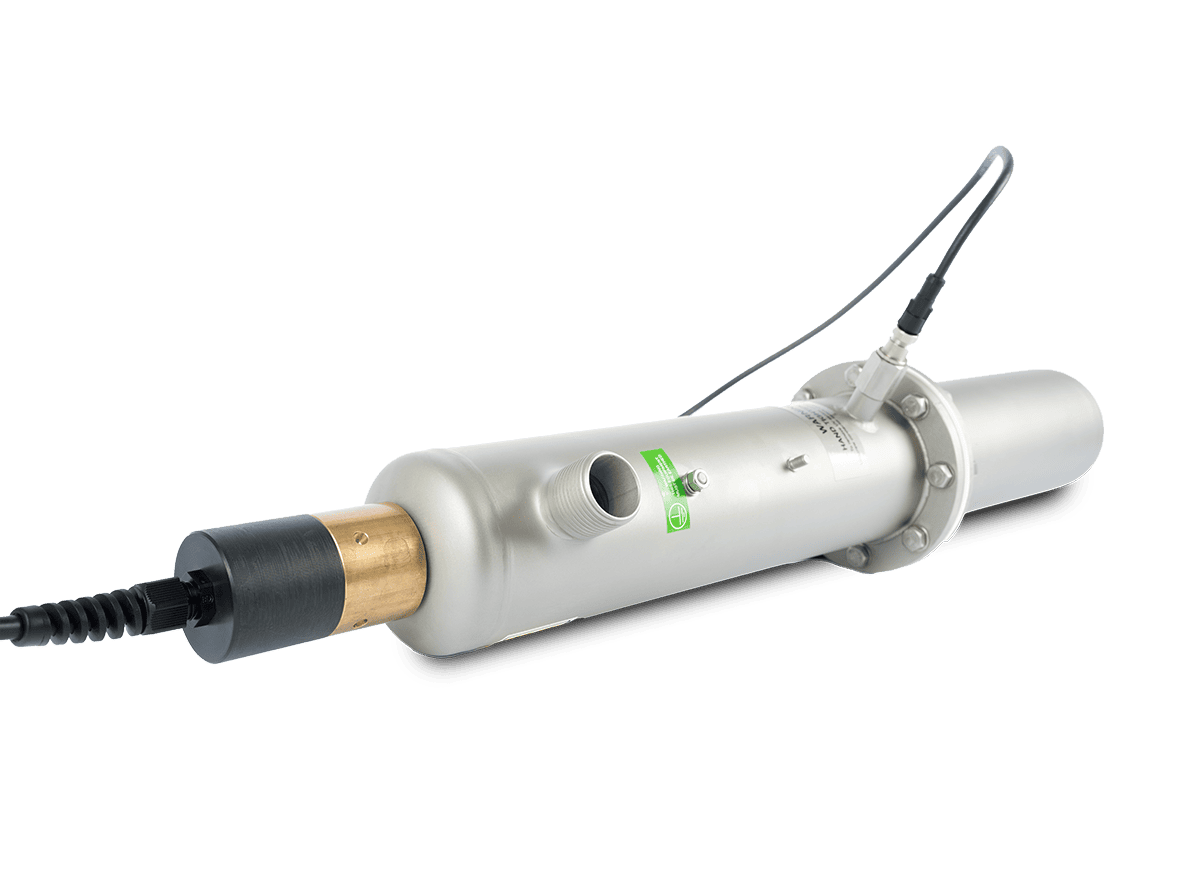

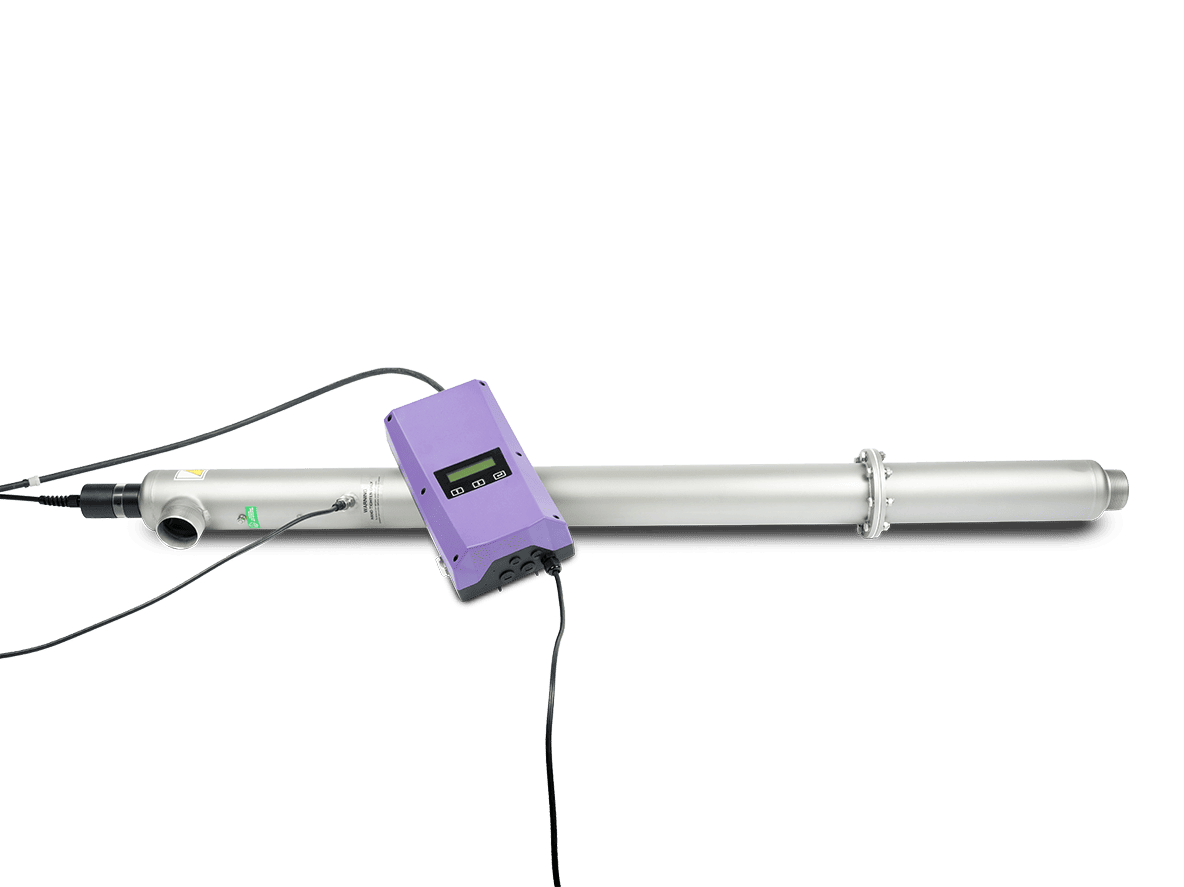

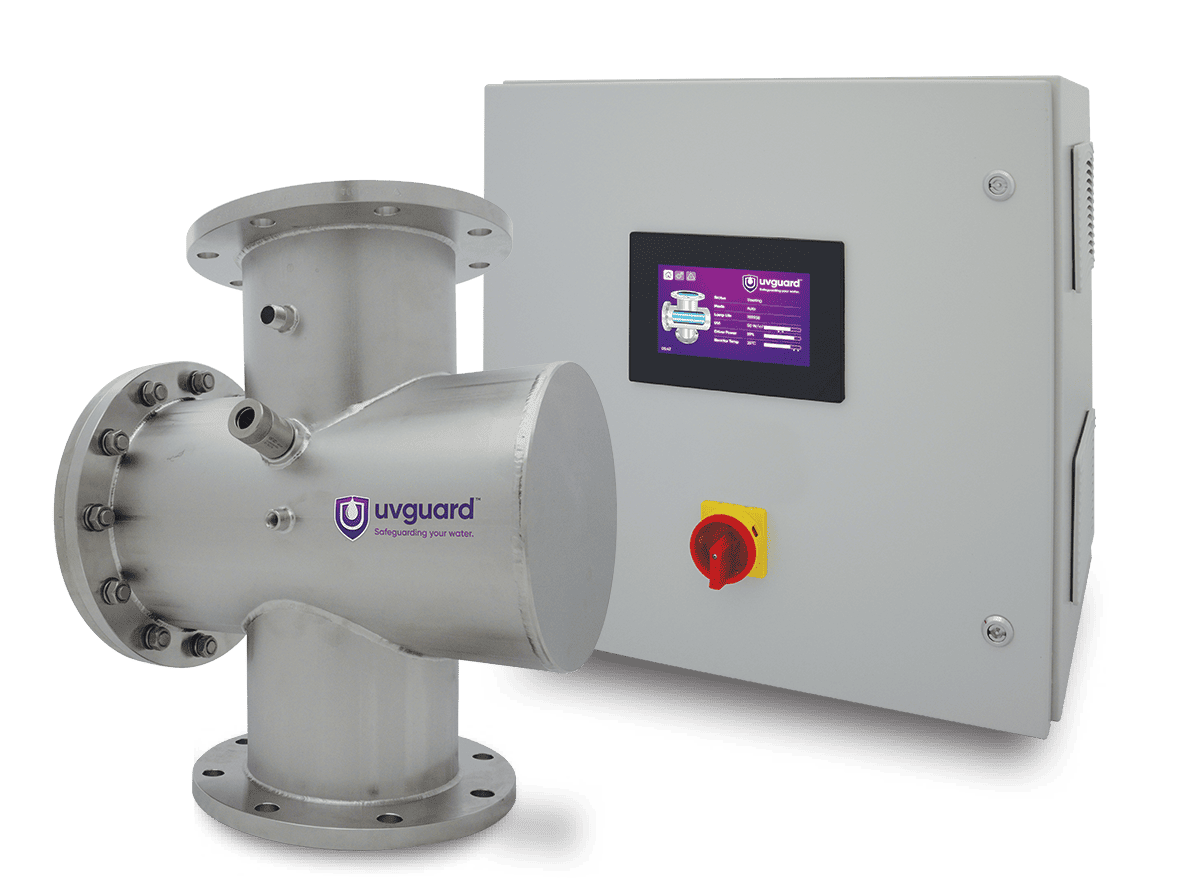

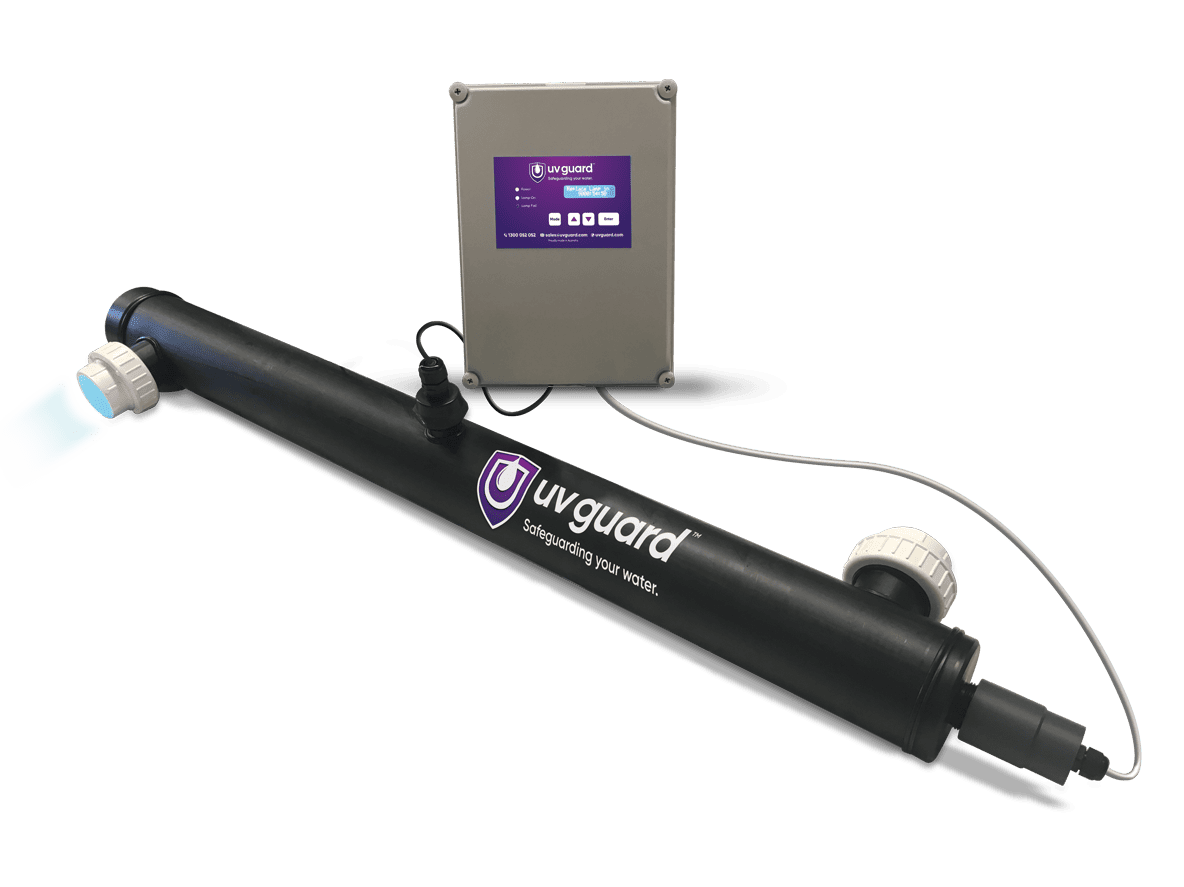

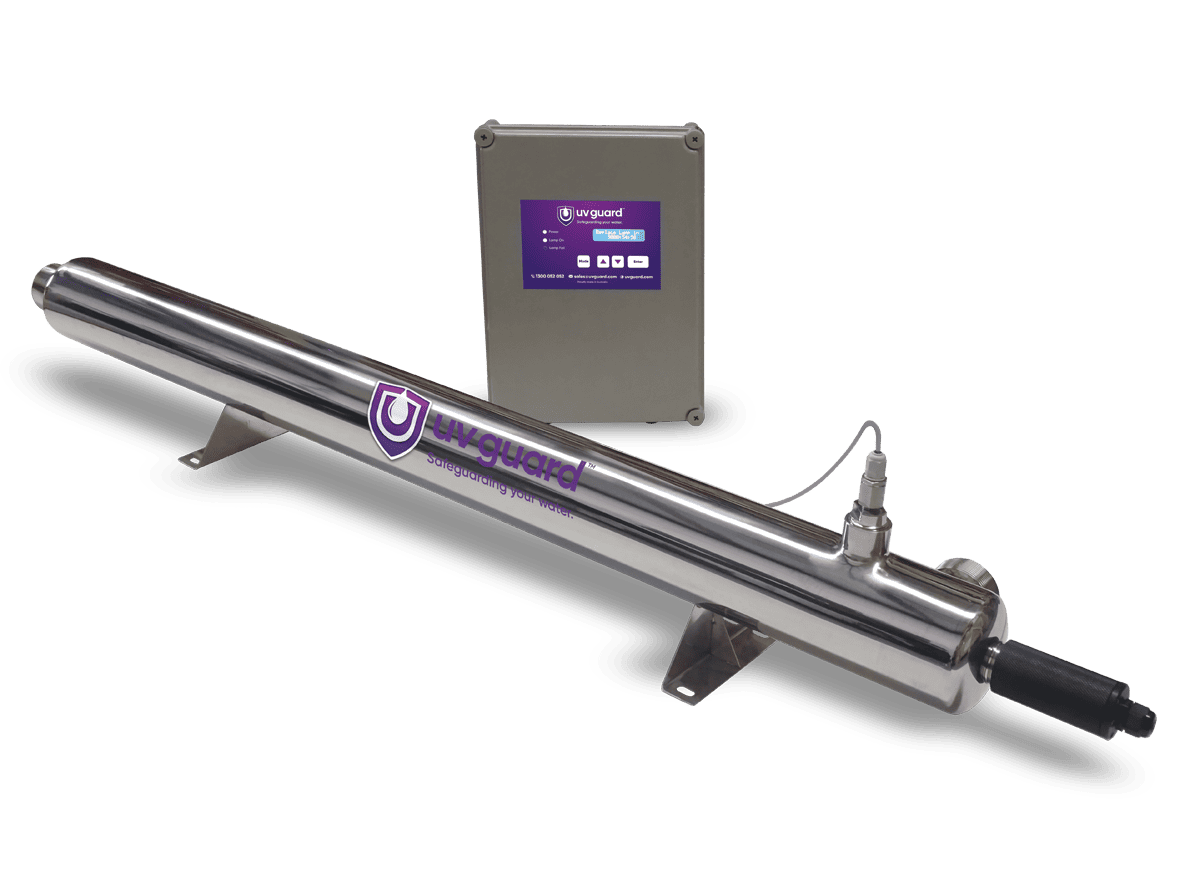

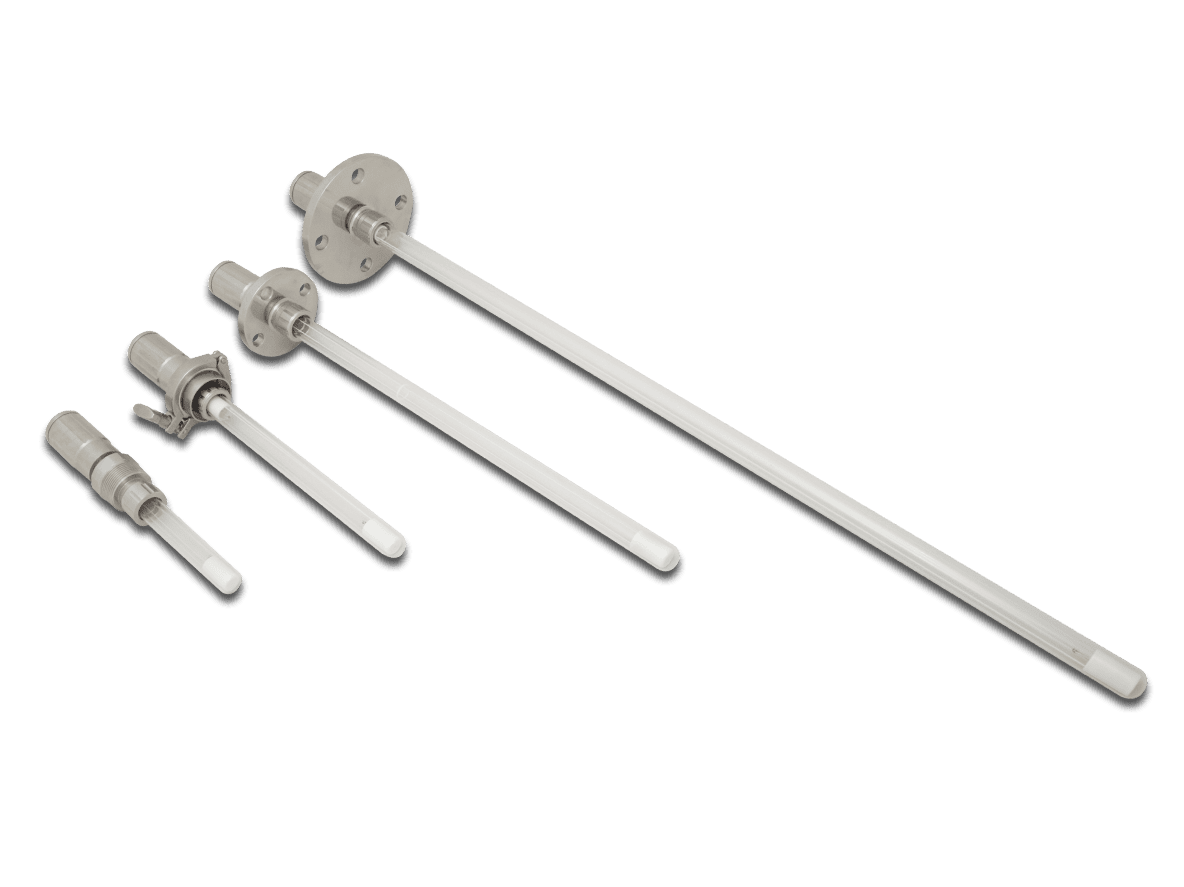

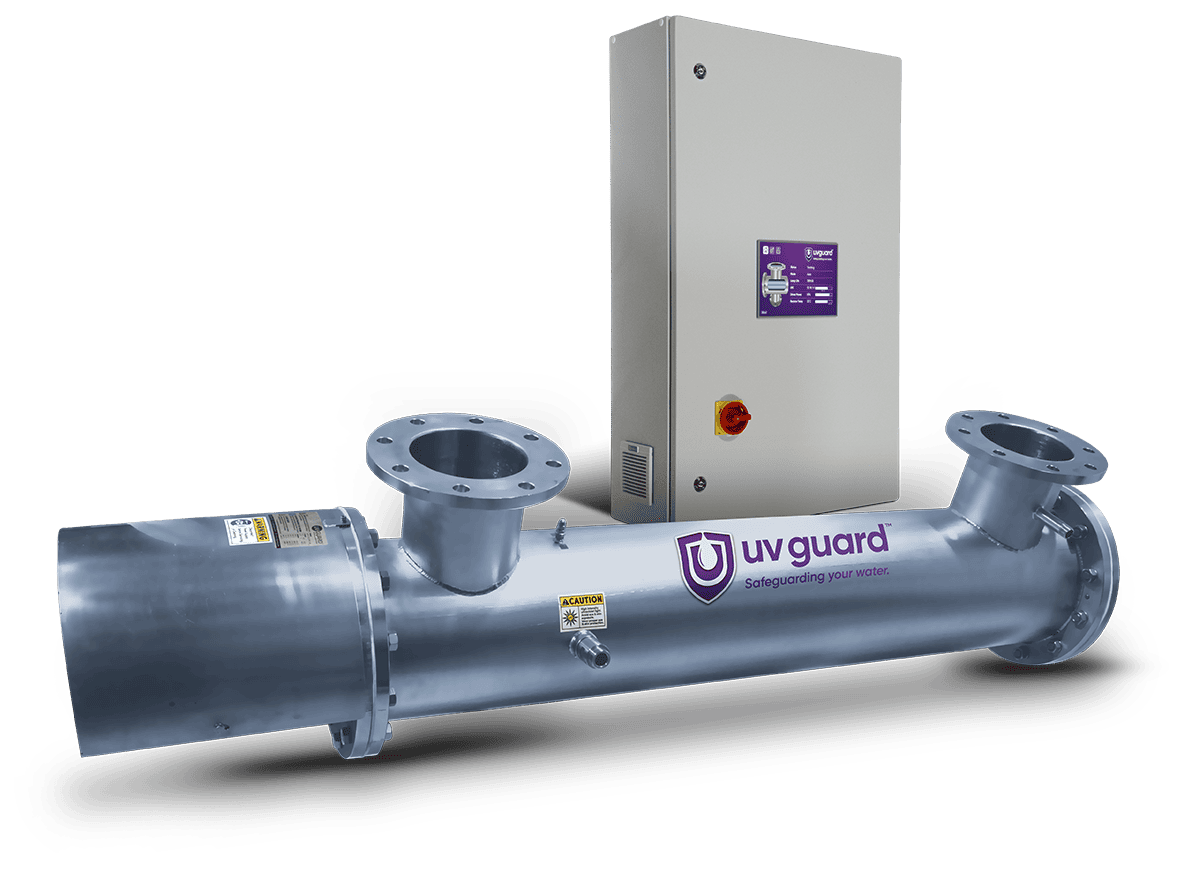

UV Disinfection Systems

Non UV Disinfection Systems

Other UV Disinfection Systems

UV Guard Applications

Our market-leading UV disinfection systems deliver outstanding results across an extensive range of industrial, commercial and domestic applications.

What Is a Commercial Water Filter?

A commercial water filter is a device that purifies water for business applications.

These systems come in various types:

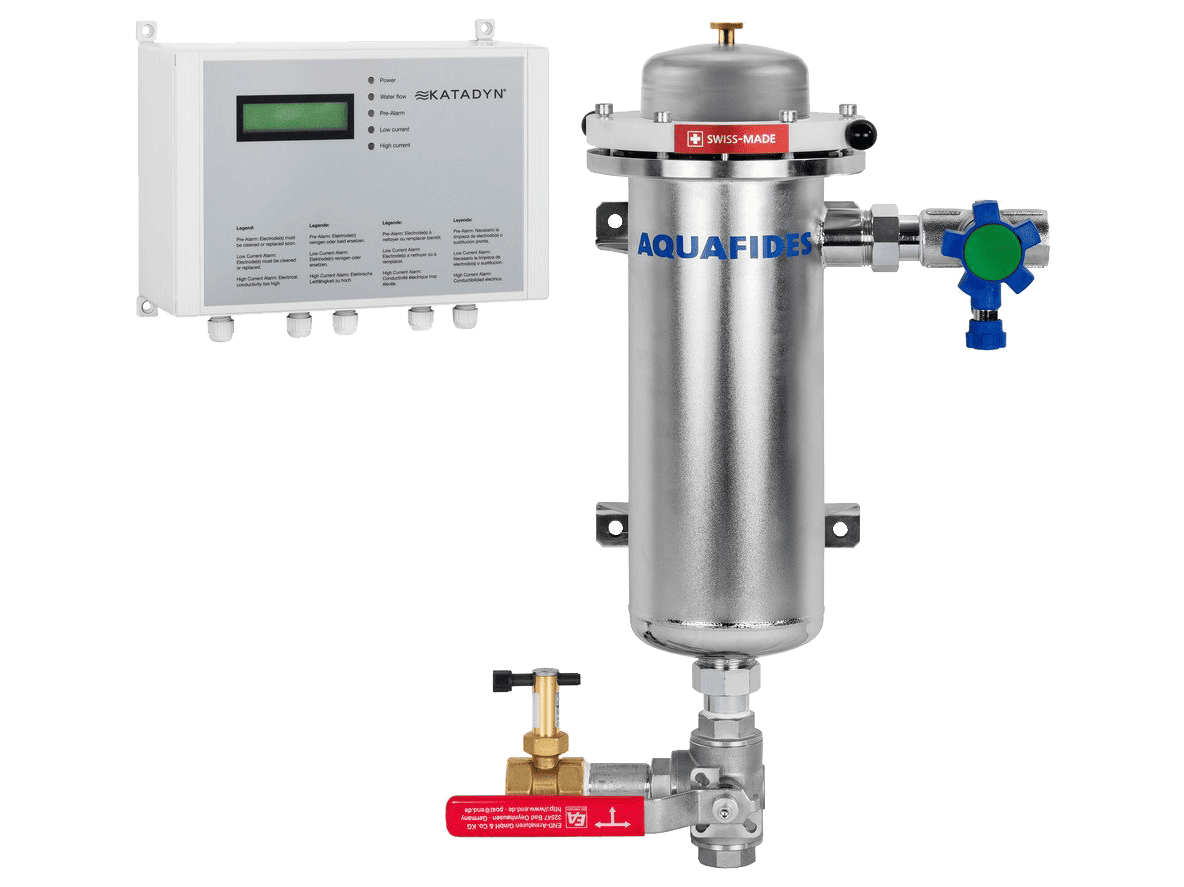

- Silver ionisation systems

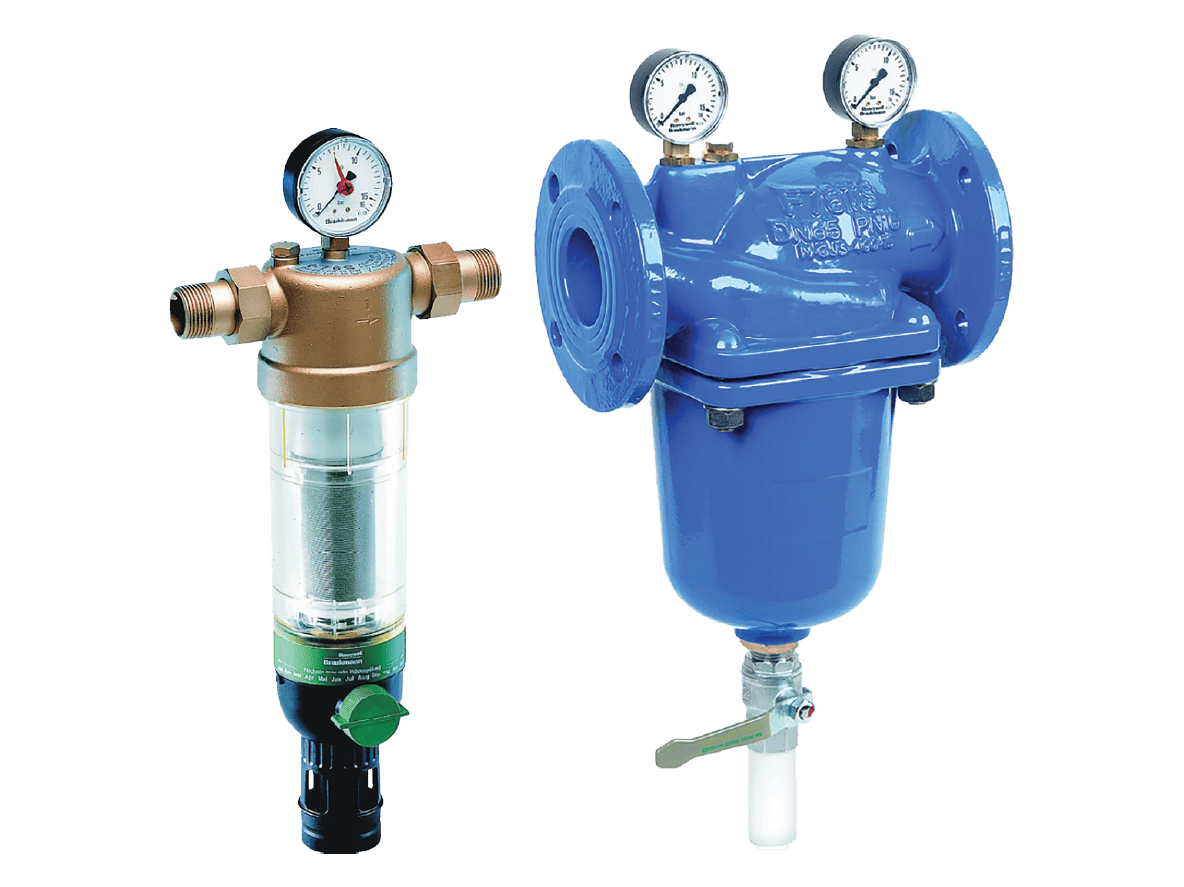

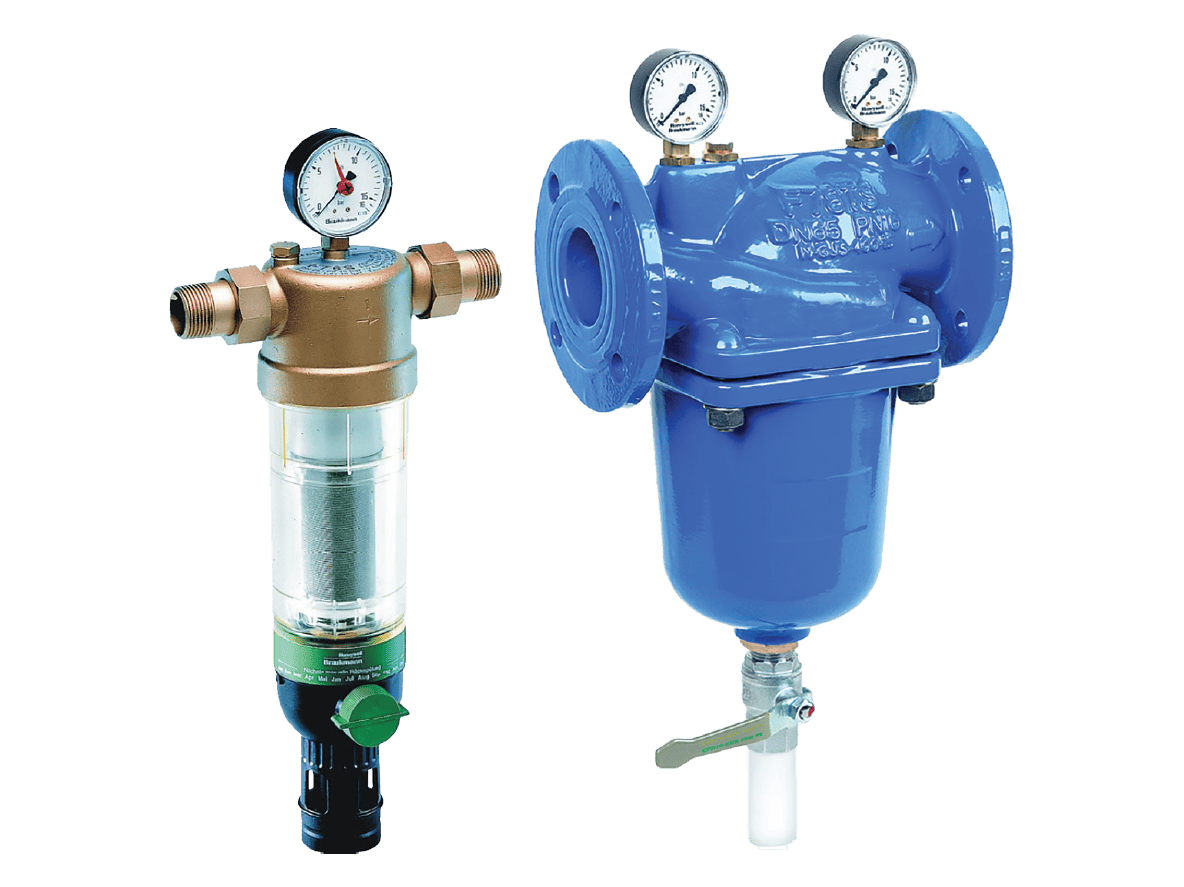

- Automatic backwashing screen water filters

- Cartridge and bag water filters

- Hard water conditioners

- UV light disinfection systems

Each system has a unique way of cleaning water, which we’ll discuss later.

Why Is Commercial Water Treatment Necessary?

First and foremost, commercial water treatment is necessary for public health. Untreated water can contain harmful bacteria, viruses, and other contaminants that could harm your employees and customers.

Second, untreated water can damage infrastructure and impact operational costs. Damage can include corroding pipes, affected boiler performance, and unsightly stains on surfaces.

Third, water quality directly affects your products and services. For example, hard water can affect the taste of coffee in a cafe, and poor water quality can jeopardise a product’s integrity in a manufacturing plant.

Lastly, there are legal implications. Many jurisdictions have water quality standards that businesses must meet, with non-compliance resulting in hefty fines or even business closure.

What Businesses and Industries Need Commercial Water Treatment Solutions?

- Agricultural facilities

- Breweries and distilleries

- Chemical plants

- Food processing plants

- Healthcare facilities

- Hotels

- Laundromats

- Manufacturing plants

- Mining operations

- Pharmaceutical facilities

- Public pools

- Restaurants and cafes

- Schools and universities

- Spas and gyms

- Textile factories

- Wastewater treatment plants

- Zoos and aquariums

Types of Commercial Water Treatment Systems

Best Commercial Water Treatment Solutions

Here at UV Guard, we specialise in the following UV commercial water treatment systems.

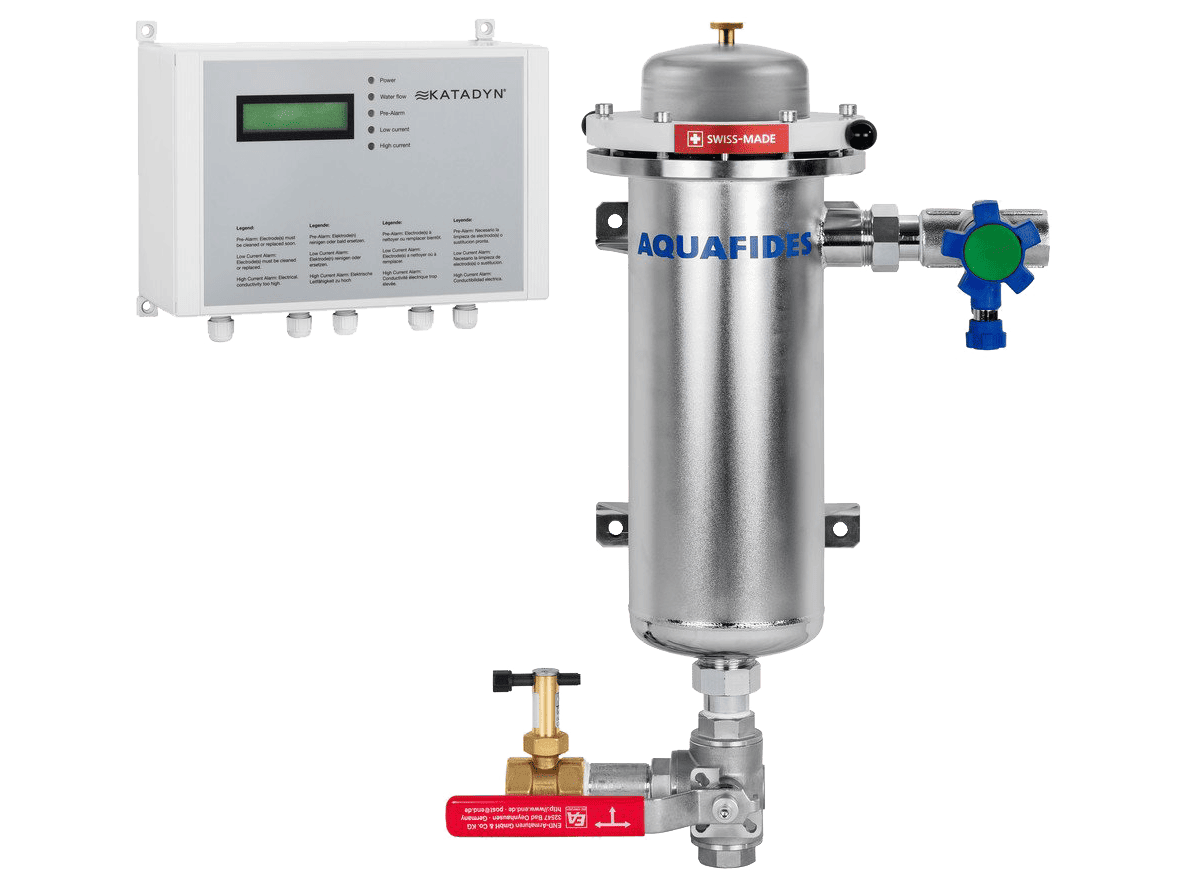

Best Non-UV Commercial Water Treatment Solutions

How Do I Choose A Commerical Water Treatment System?

- Identify your needs: Do you need to remove sediment, soften hard water, or eliminate bacteria? Knowing your specific water issues will guide you to the right commercial water treatment system.

- Flow rate: Check the flow rate your business needs, usually measured in litres per minute (LPM). Make sure the system can handle the volume of water your business uses.

- Maintenance: Some systems need frequent filter changes, while others are more set-and-forget. Choose one that suits your maintenance capability.

- Installation: Some systems are easy to install, while others may require professional setup. Consider installation costs and complexity.

- Budget: Systems vary in price. Balance your budget against your needs to find a system that delivers value.

- Regulatory compliance: Ensure the system meets local and national water safety standards.

FAQs About Commercial Water Treatment

Do You Have Questions About the Best Commercial Water Treatment System for Your Business?

Choosing a water treatment system for your business is like finding the right captain for your boat. You need someone—or, in this case, something—that can navigate through all kinds of waters for a smooth and safe journey.

The expert team at UV Guard is here to steer you toward crystal-clear waters with our UV and non-UV commercial water treatment systems.

Fill in the online form, and we’ll be in touch soon to help you find the right system for your business.

Get in touch

This website has lots about us.

But it’s your needs that matter most.

Let’s talk.

Newsletter

Stay up-to-date with our very latest news, technology, offers and events.