Aquaculture

A more sustainable and cost-effective solution to protect fish, shellfish and crustaceans at each stage of the farming process.

UV Water Disinfection for Aquaculture

Poor inflow water quality, recirculation of tank water contaminated by fish diseases and discharging of pathogenic effluents can cause the failure of an aquaculture operation. UV disinfection is a versatile and proven method to eradicate these risks.

There are no aquaculture microorganisms known to be immune to UV Disinfection. As it is a chemical-free process, there is no risk of overdosing or formation of by-products, resulting in a process that is environmentally friendly and safe for fish and humans.

UV Guard has custom UV disinfection and treatment solutions for the following fresh water, brackish water and sea water aquaculture applications:

- Fish, crustacean and shellfish farming – improve quality and increase production yields

- Recirculating Aquaculture Systems (RAS) – ensure your systems are free from pathogens and allow higher densities of fish to be farmed safely

- Hatcheries – safeguard broodstock, hatching fish, larvae and fry by using non chemical pathogen protection methods at this highly sensitive farming stage

- Marine well boats – protect fish stocks during transportation to and from aquaculture farming facilities

- Aquariums and zoos – allow marine life to flourish whilst ensuring aquatic life is appreciated clearly by attraction visitors

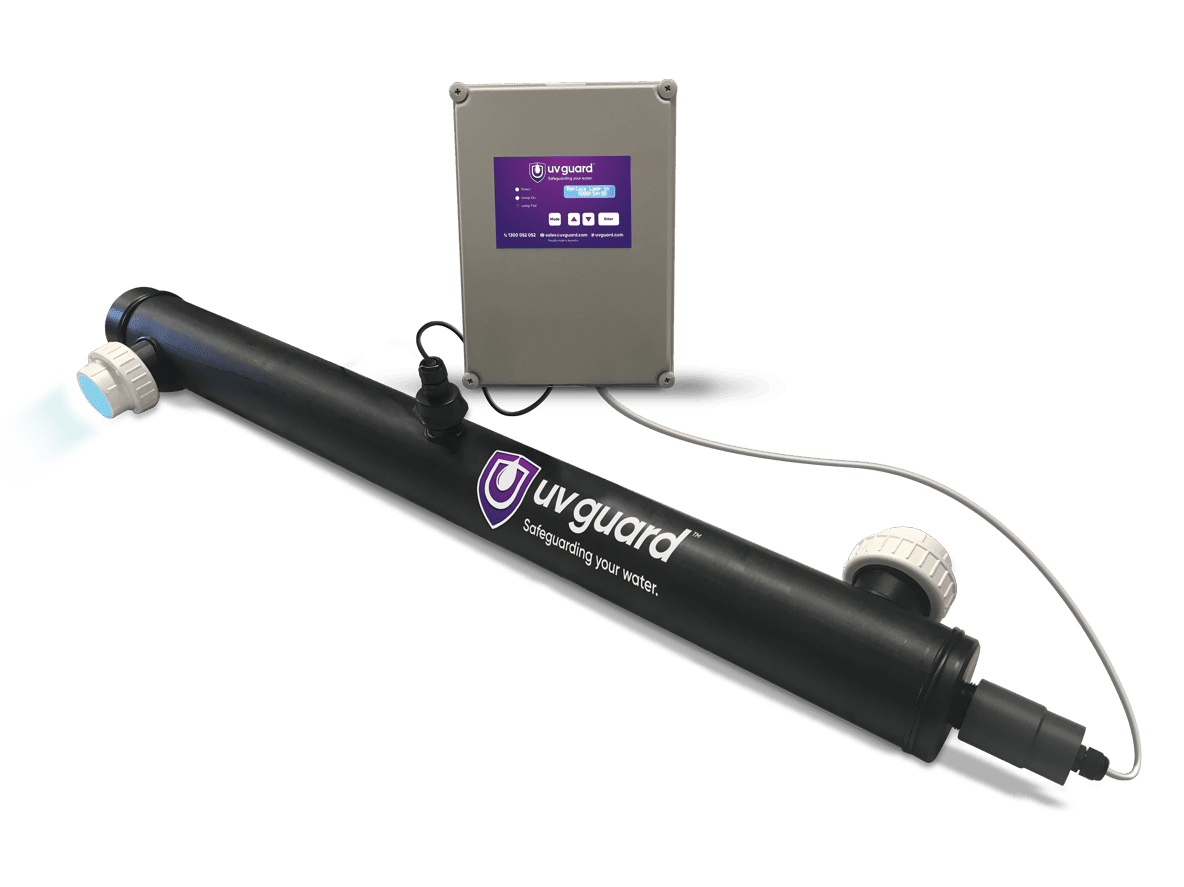

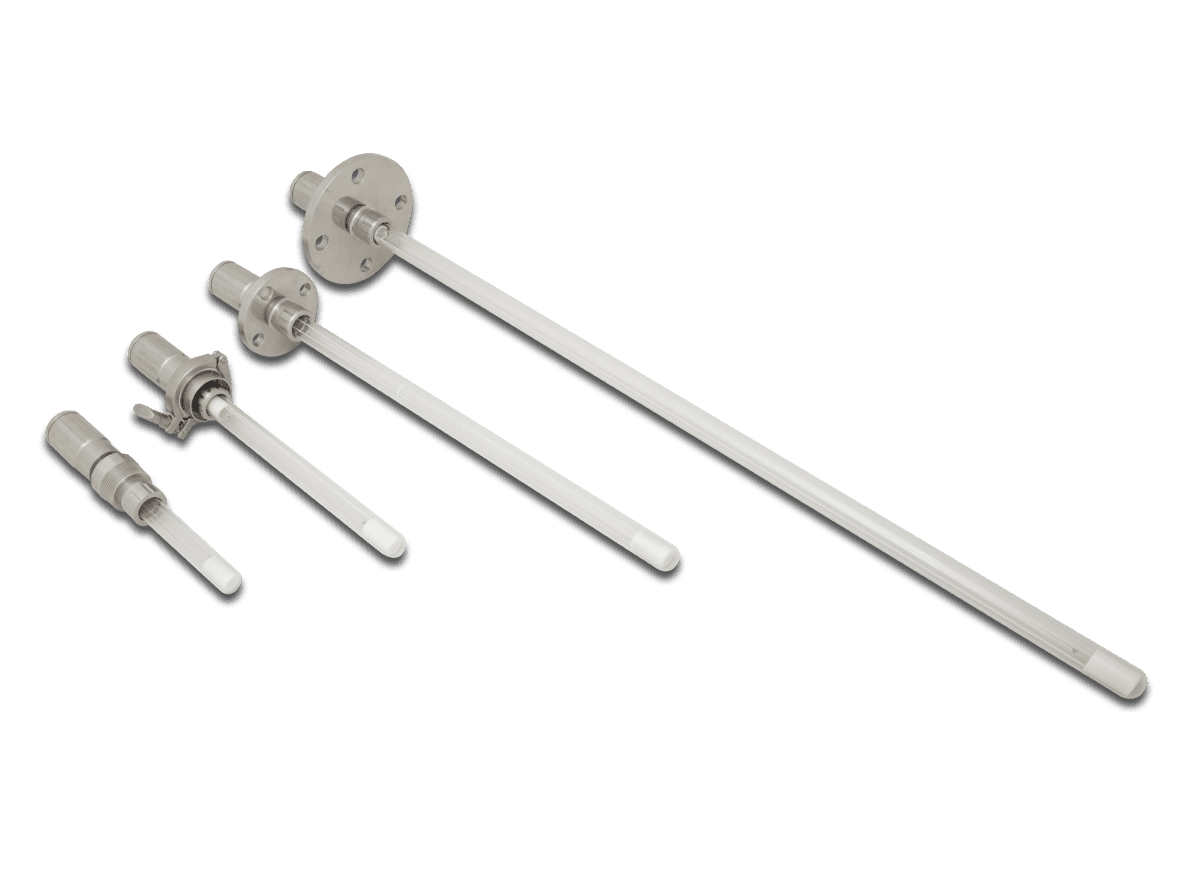

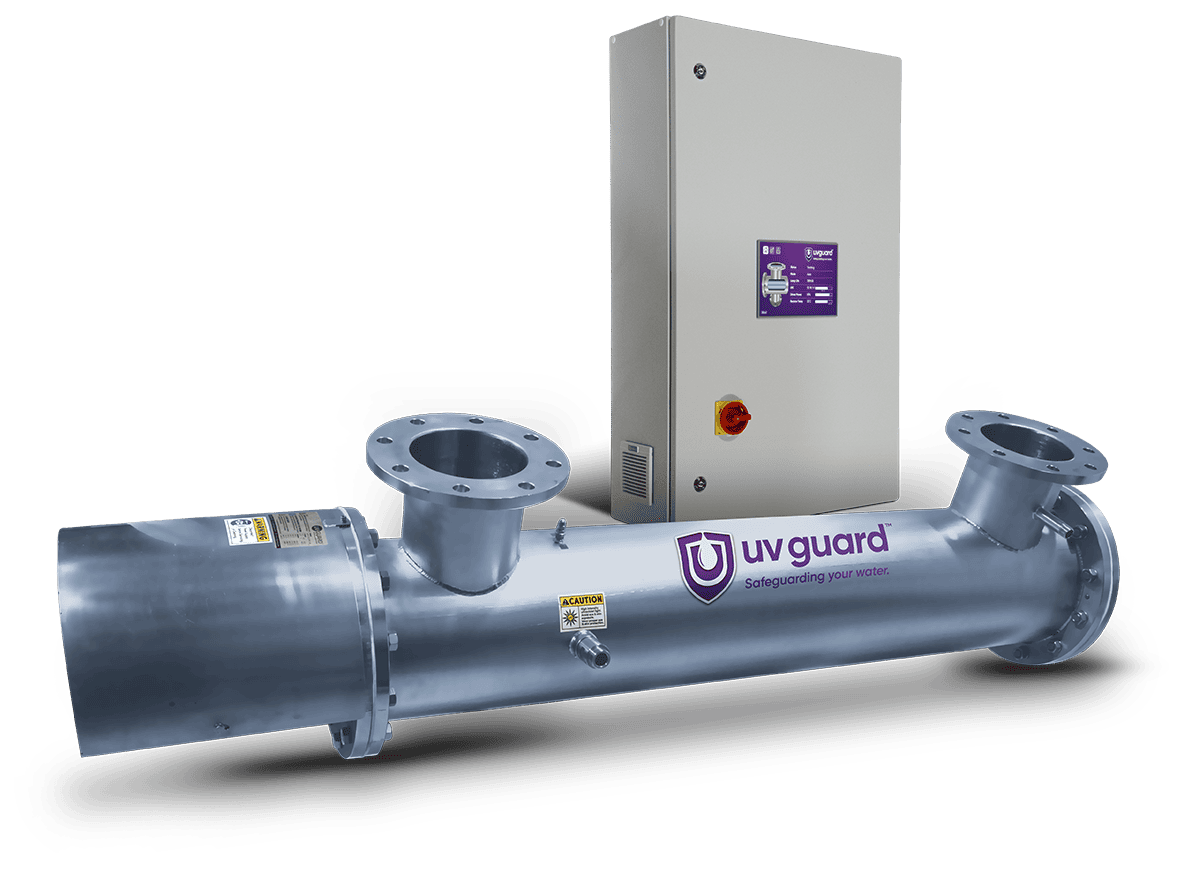

Related Products

Case Studies

Freshwater Systems Australia Case Study – UV Guard

Discover how Freshwater Systems Australia and UV Guard's strategic partnership drives success in delivering water treatment solutions across healthcare, pharmaceutical, and domestic industries. Learn about our collective technical expertise, and commitment to meeting stringent water quality guidelines.

Stopping the spread of viruses in aquaculture research facility

The aquaculture facility had multiple research stations all independently researching different fish species at the same time, and each one of these stations required its own UV system to treat the water entering that specific area. Additionally, all seawater entering the research facility needed to be treated. All UV systems needed to be selected to achieve minimum UV doses to achieve sufficient inactivation of viruses such as white spot.

Underwater World – UV disinfection for sea water aquarium

Underwater World in central Mooloolaba, located in the heart of Queensland’s famous Sunshine Coast is renowned for being the area’s top family attraction. The aquarium is home to a range of marine life including fish, sea animals and corals. The marine life must be protected from a range of diseases including bacteria, fungi, viruses and protozoa.

Get in touch

This website has lots about us. But it’s your needs that matter most. Let’s talk.

Newsletter

Stay up-to-date with our very latest news, technology, offers and events.