Customer

Nu-Pure Beverages, QLD and VIC

Application

Natural spring water treatment

Project Background

Nu-Pure Beverages are a 100% Australian owned business who produce bottled spring water and other beverages. Their spring water is sourced from specially selected pristine Australian springs, pure with a natural balance of minerals.

Nu-Pure pride themselves on producing a natural product and sustainability is an important factor in everything they do. The spring water they use must be free from bacteria and other pathogens. The taste and odour of the product must also not be detrimentally impacted by any water treatment processes used.

UV disinfection was selected by the Nu-Pure process engineers as a safe, reliable and cost effective method to disinfect the spring water at a number of stages in their manufacturing processes. As UV disinfection is a chemical and bi-product free process, it was the ideal solution to safeguard the water being produced without adversely affecting its taste and odour.

Nu-Pure contacted UV-Guard with requirements for UV disinfection units at three stages of their manufacturing processes, two stages in their Victoria manufacturing plant and one stage at their Queensland manufacturing plant.

UV Requirements

- WaterMark certified UV reactors – Food grade compliant

- UV dose of 40 mJ/cm²

- UV Transmittance (% UVT) of 96%

UV Guard’s Solution

| Stage | Peak flow rate | Solution |

|---|---|---|

| VIC – Pre storage tank between pre filtration processes | 60m3 | UVG X3-440 |

| VIC – Post storage tank treatment prior to silver and final filtration | 2 x 20m3 | 2 x UVG S440 |

| QLD – Post storage tank treatment prior to silver and final filtration | 2 x 20m3 | 2 x UVG S440 |

UVG X3-440

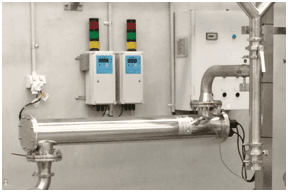

The UVG X3-440 is a WaterMark certified multi-lamped system with three 450W UV lamps designed for food grade applications where a large treatment flow is required. The unit is installed with a UV intensity monitor to alert Nu-Pure whenever the design UV dose is in risk of not being achieved. This could be as a result of water quality deterioration, quartz tube fouling or lamp failure.

2 x UVG S440 systems in parallel

The a UVG S440 system is also WaterMark certified. Two units were installed in parallel at both the VIC and QLD manufacturing plants. The UVG S440 systems were also installed with UV intensity monitors. Installing two units in parallel allows for a level of redundancy. If one unit is out of action for servicing, disinfected water can still be achieved though the other system.

Bruce Taylor – National Technical Manager of Nu-Pure Beverages

“I would recommend UV-Guard as a supplier of quality, dependable UV equipment with excellent back up service and support.

The UV-Guard equipment is an integral part of our Quality Management System and HACCP program to ensure a safe, quality product is continuously produced in our bottling plants.”

If you have a food and beverage water treatment enquiry, contact a UV Guard process engineer today.

Freshwater Systems Australia Case Study – UV Guard

Discover how Freshwater Systems Australia and UV Guard's strategic partnership drives success in delivering water treatment solutions across healthcare, pharmaceutical, and domestic industries. Learn about our collective technical expertise, and commitment to meeting stringent water quality guidelines.

Stopping the spread of viruses in aquaculture research facility

The aquaculture facility had multiple research stations all independently researching different fish species at the same time, and each one of these stations required its own UV system to treat the water entering that specific area. Additionally, all seawater entering the research facility needed to be treated. All UV systems needed to be selected to achieve minimum UV doses to achieve sufficient inactivation of viruses such as white spot.

Get in touch

This website has lots about us. But it’s your needs that matter most. Let’s talk.

Newsletter

Stay up-to-date with our very latest news, technology, offers and events.