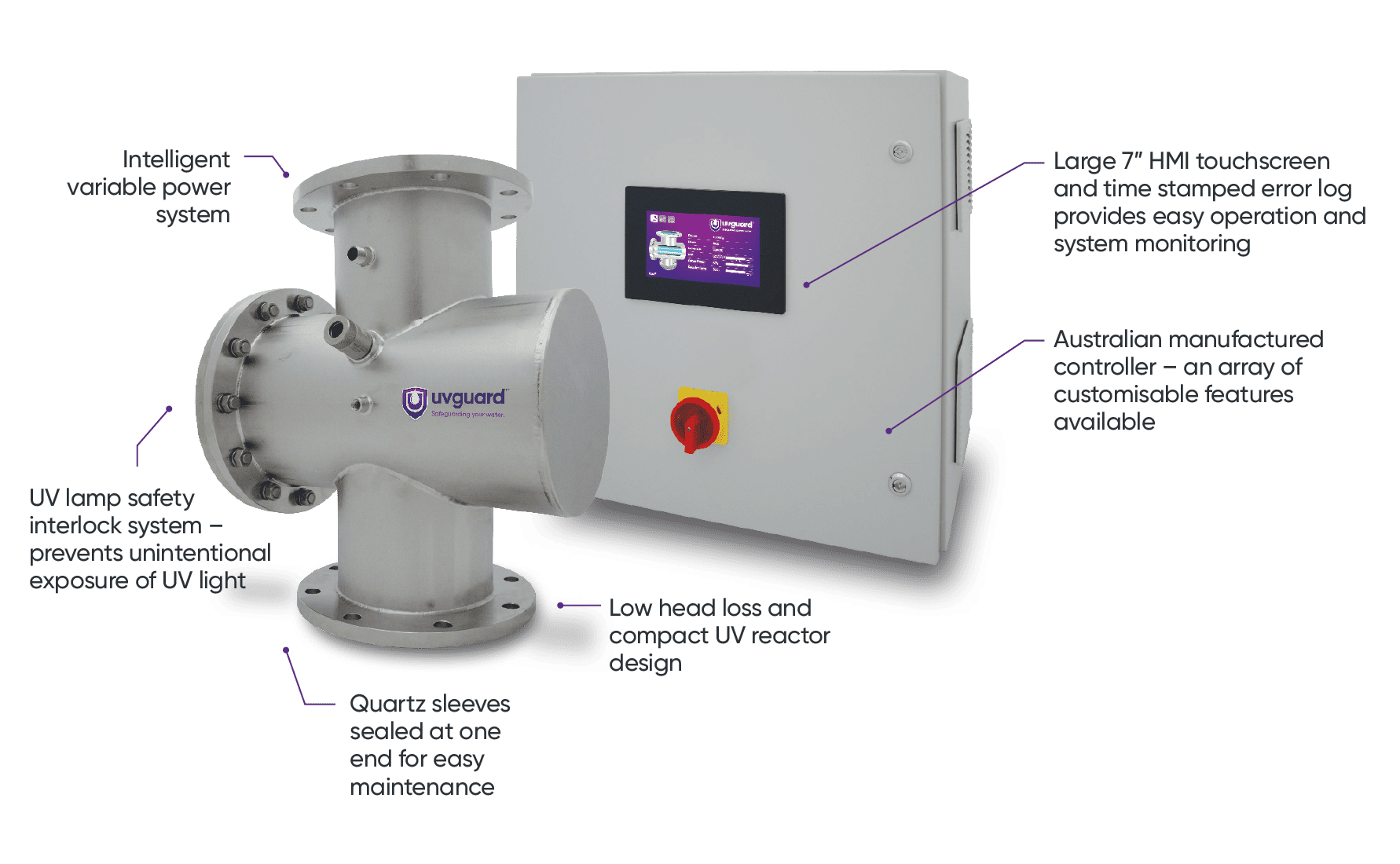

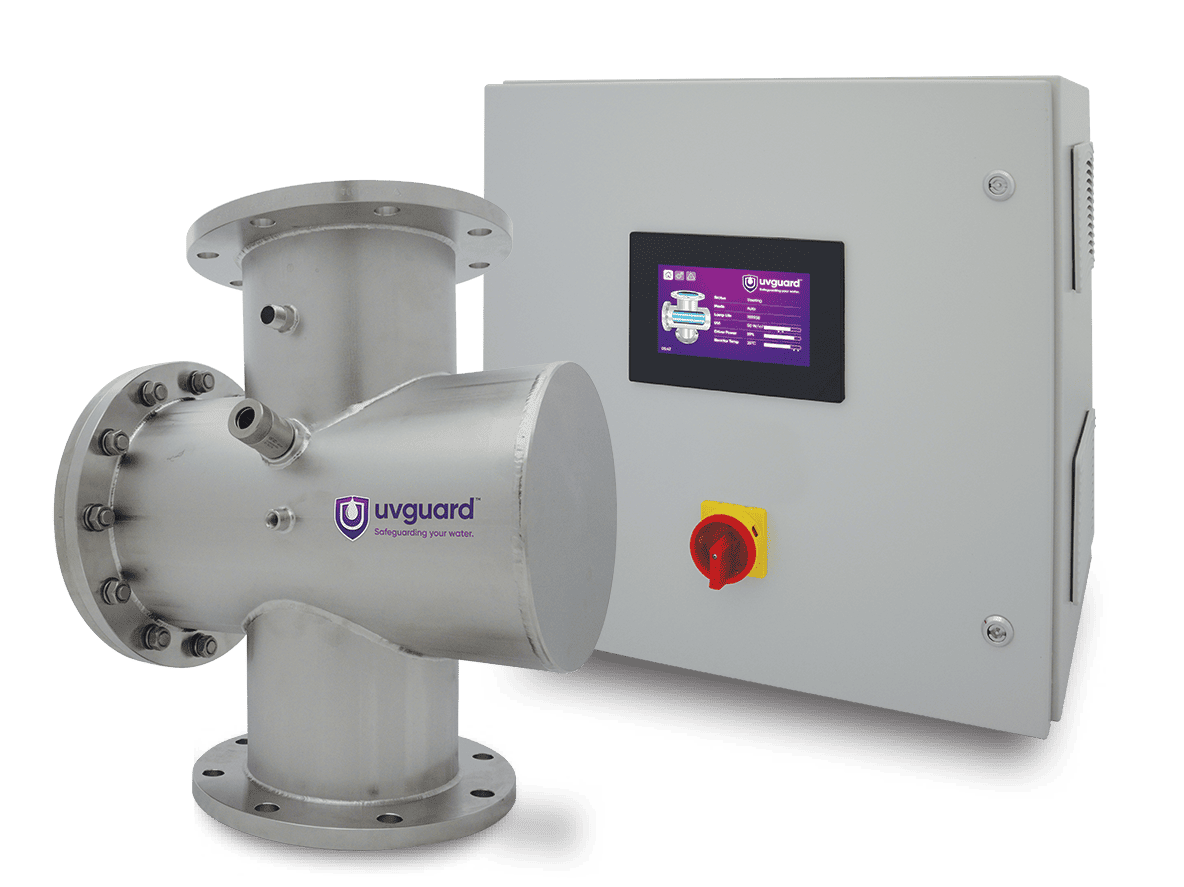

MPX-Series™

Performance-optimised medium pressure UV treatment for commercial applications.

Product Information

UV Guard’s MPX-Series offers compact, high-performance medium pressure UV systems for flows up to 1000m3/hr. Variable power polychromatic UV lamp drivers deliver market-leading efficiency with smooth automatic dimming for ‘Optimised’ and customised ‘User Profile’ power modes. The MPX-Series is ideal for commercial swimming pools, water features, industrial process water, wastewater and potable water applications.

Testimonials

Get in touch

This website has lots about us. But it’s your needs that matter most. Let’s talk.

Newsletter

Stay up-to-date with our very latest news, technology, offers and events.