UV Disinfection for Food & Beverage Applications

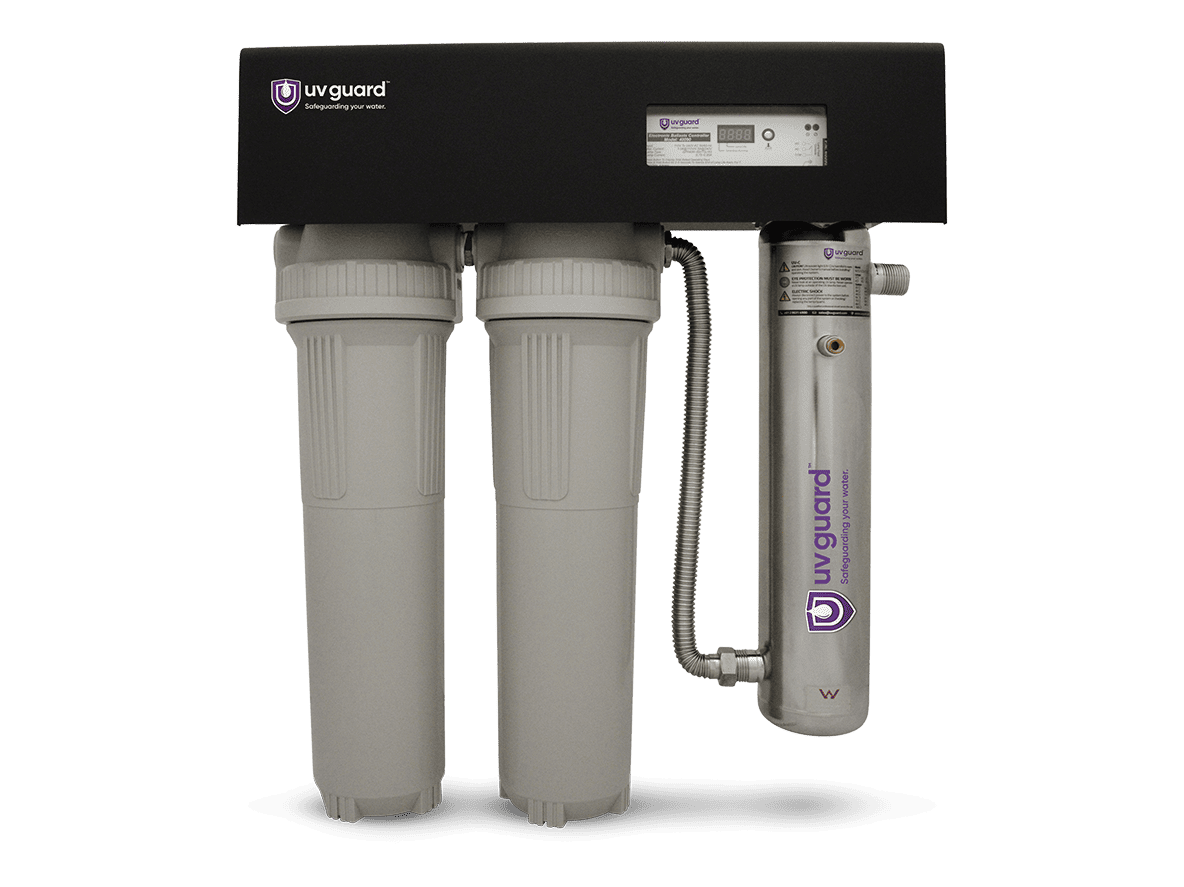

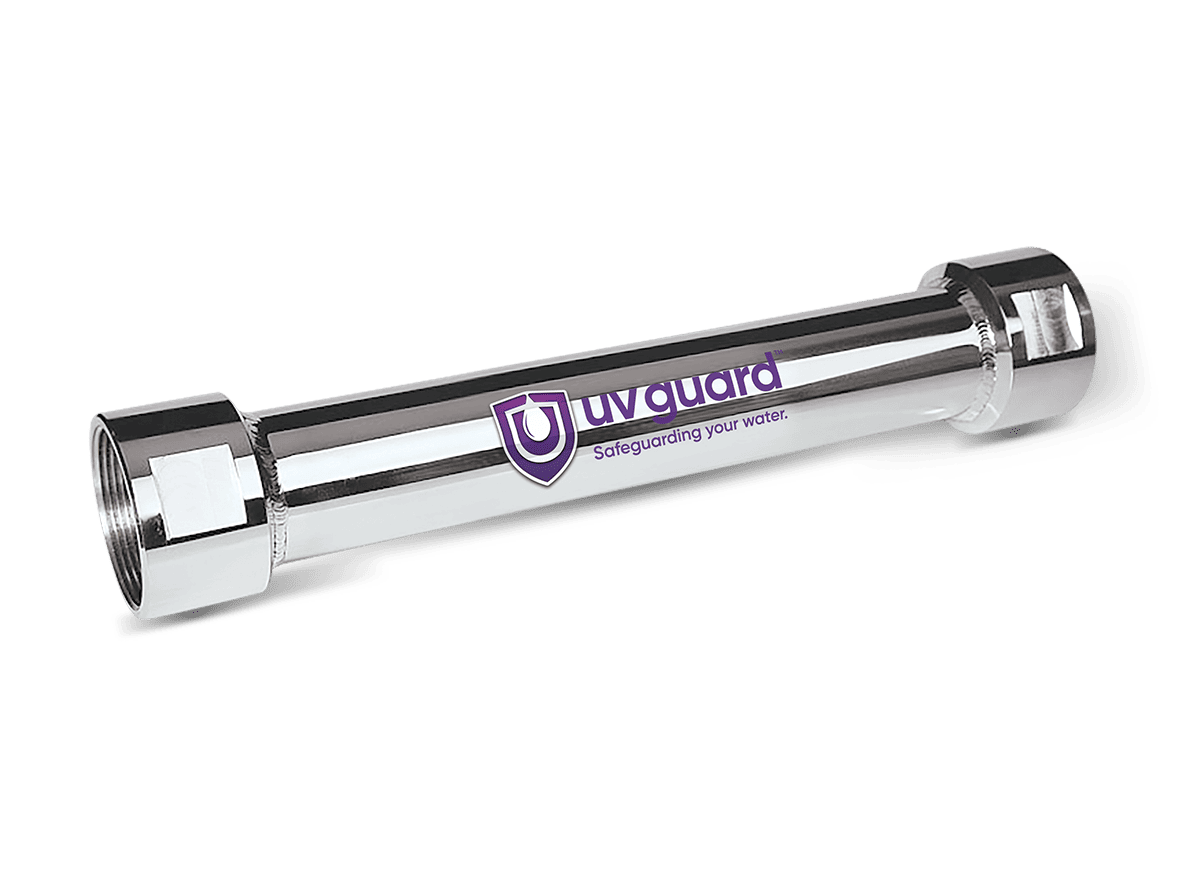

UV Guard supports the food and beverage industry with reliable, chemical-free food and beverage UV water treatment solutions. Our systems help maintain product quality by reducing microbial contamination risks in water and liquid ingredients. Designed for operational safety and sustainability, our UV water treatment for food and beverage industries helps production teams stay compliant and minimise downtime.

Reliable UV Water Treatment for Food and Beverage Applications

UV water treatment for food and beverage industries plays a key role in safeguarding products from contamination. Biological impurities in ingredient water or production liquids can compromise batch consistency and safety, potentially leading to costly recalls, damaged reputation and regulatory action. UV Guard systems offer dependable microbial control without introducing any chemicals into your process.

Our systems deactivate or destroy bacteria, viruses, spores, yeast, moulds, algae and protozoa. This is especially useful in processes involving liquid sugar, sugar syrup and ingredient water, where clarity, purity and taste are critical. UV disinfection also supports compliance with global food safety standards while reducing reliance on manual sanitisation or chemical-based dosing.

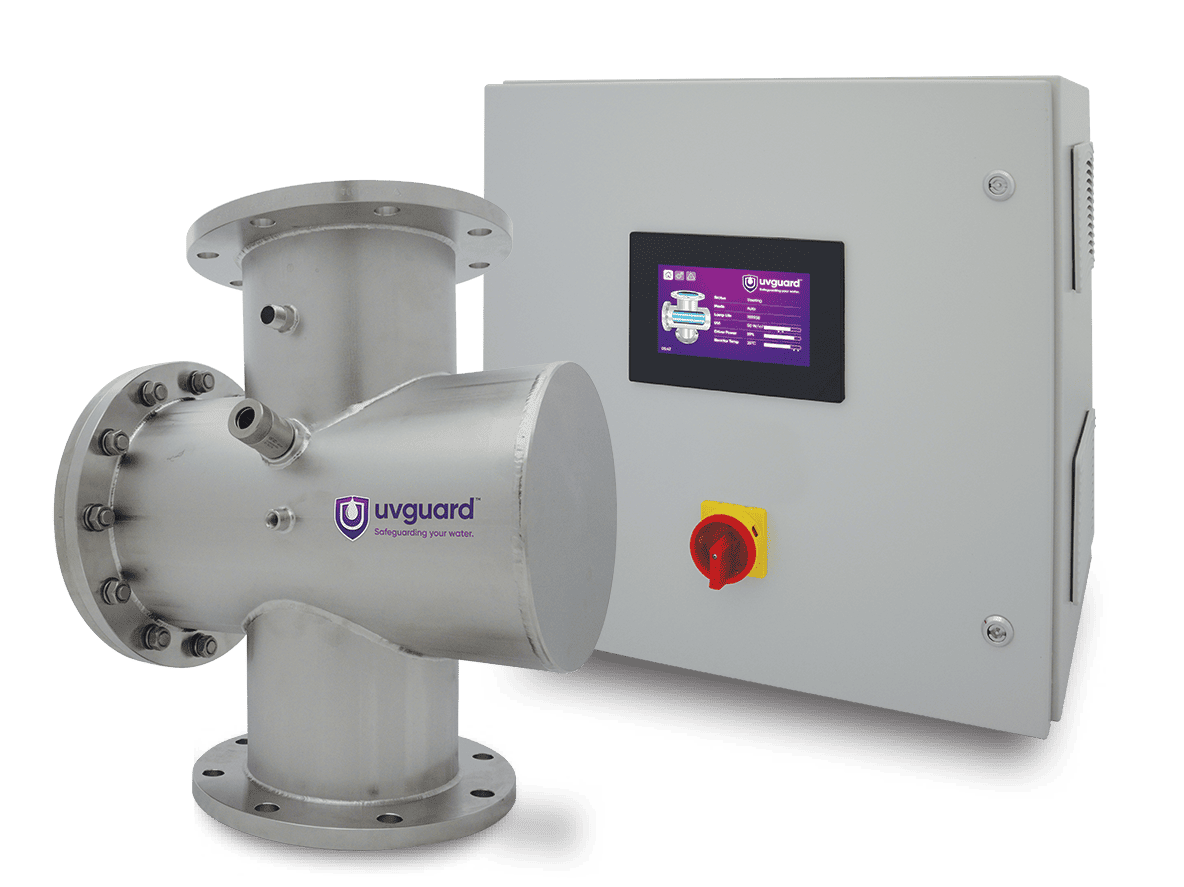

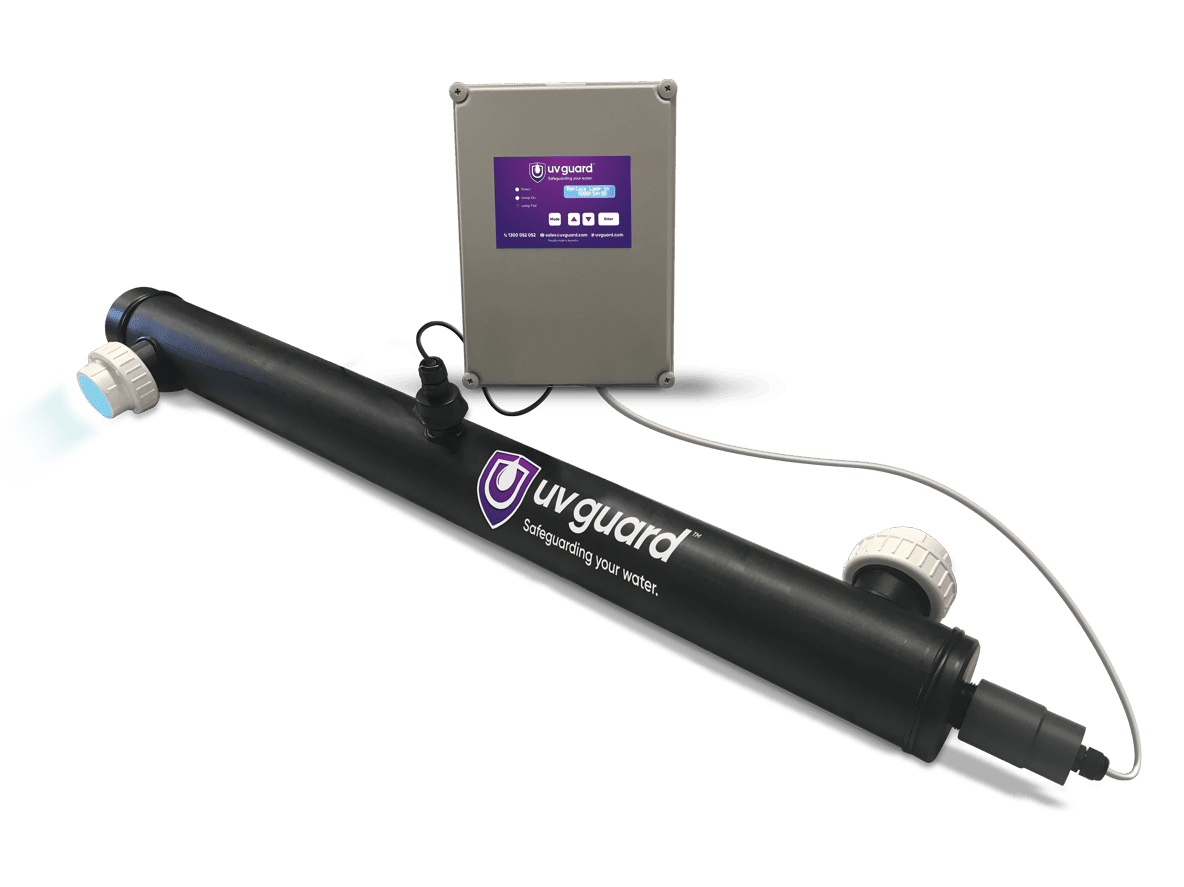

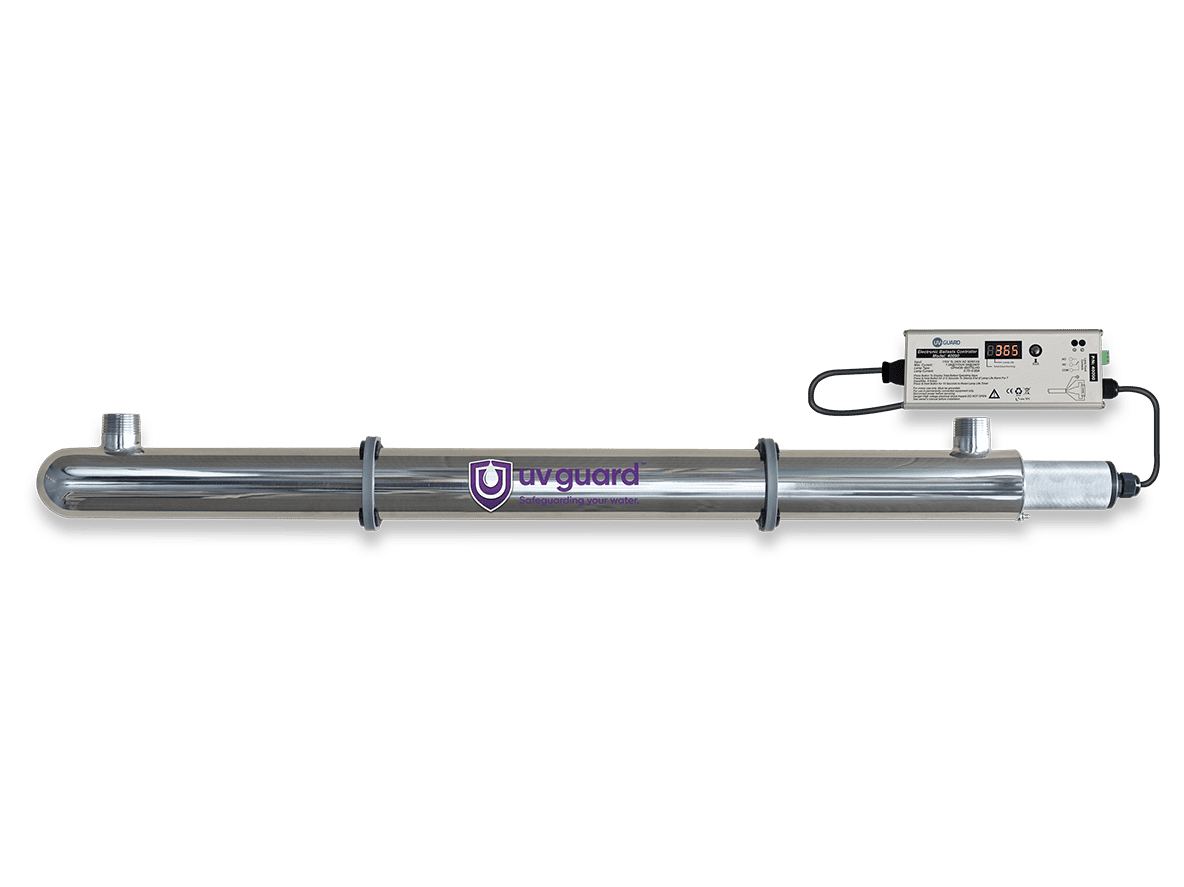

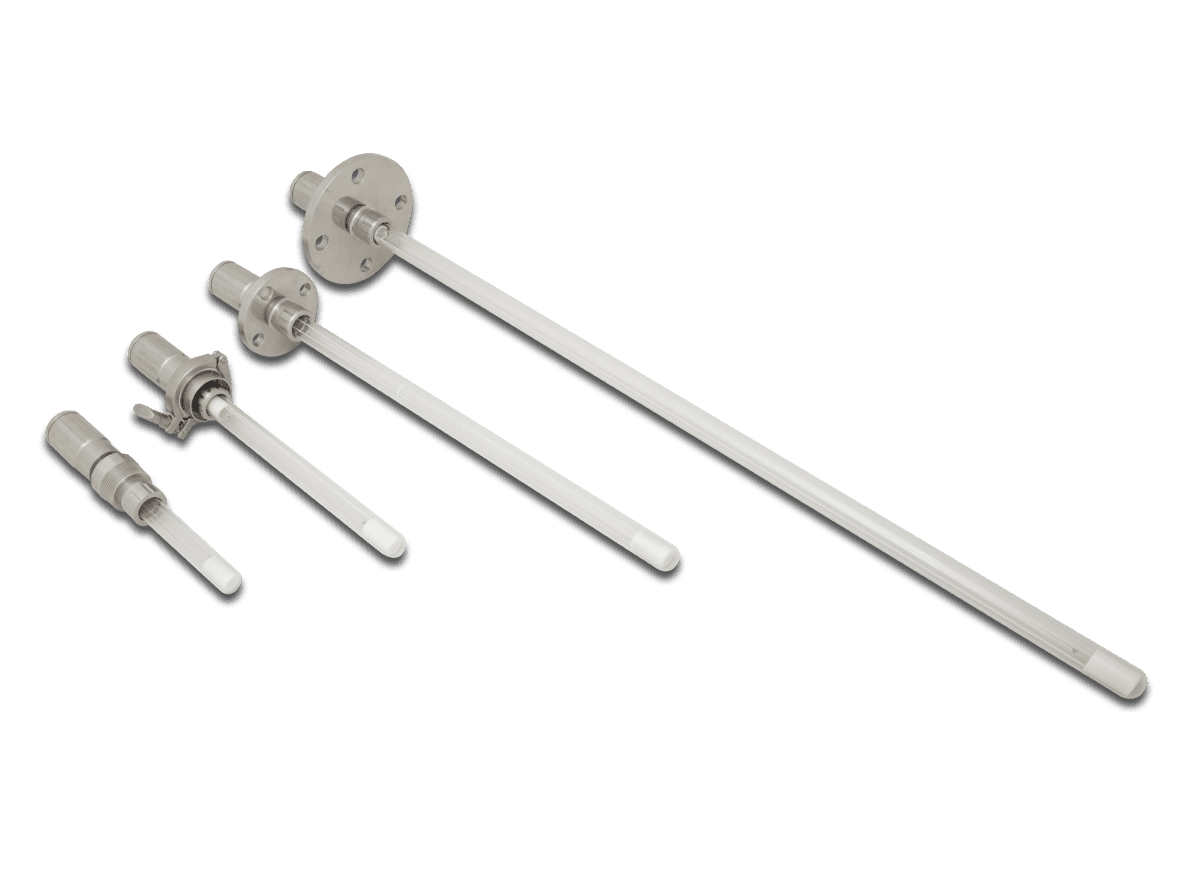

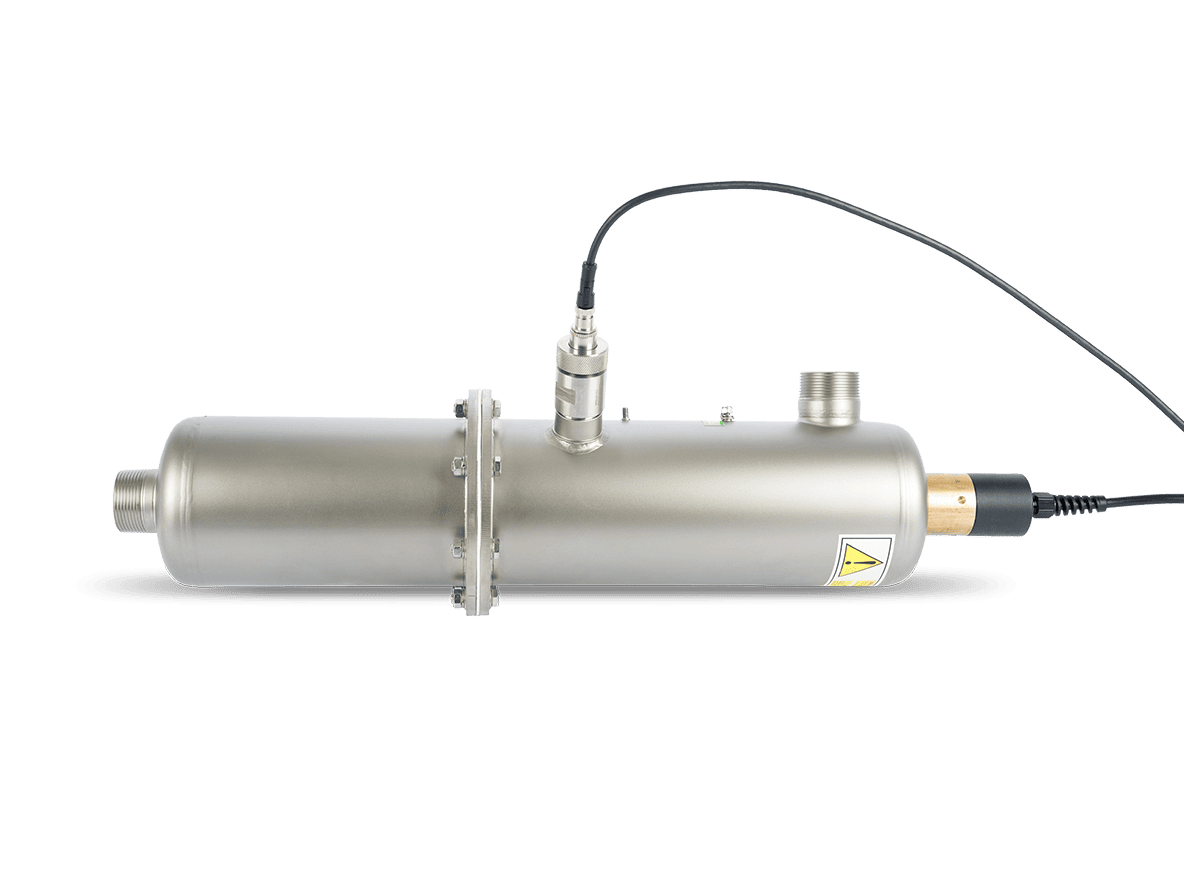

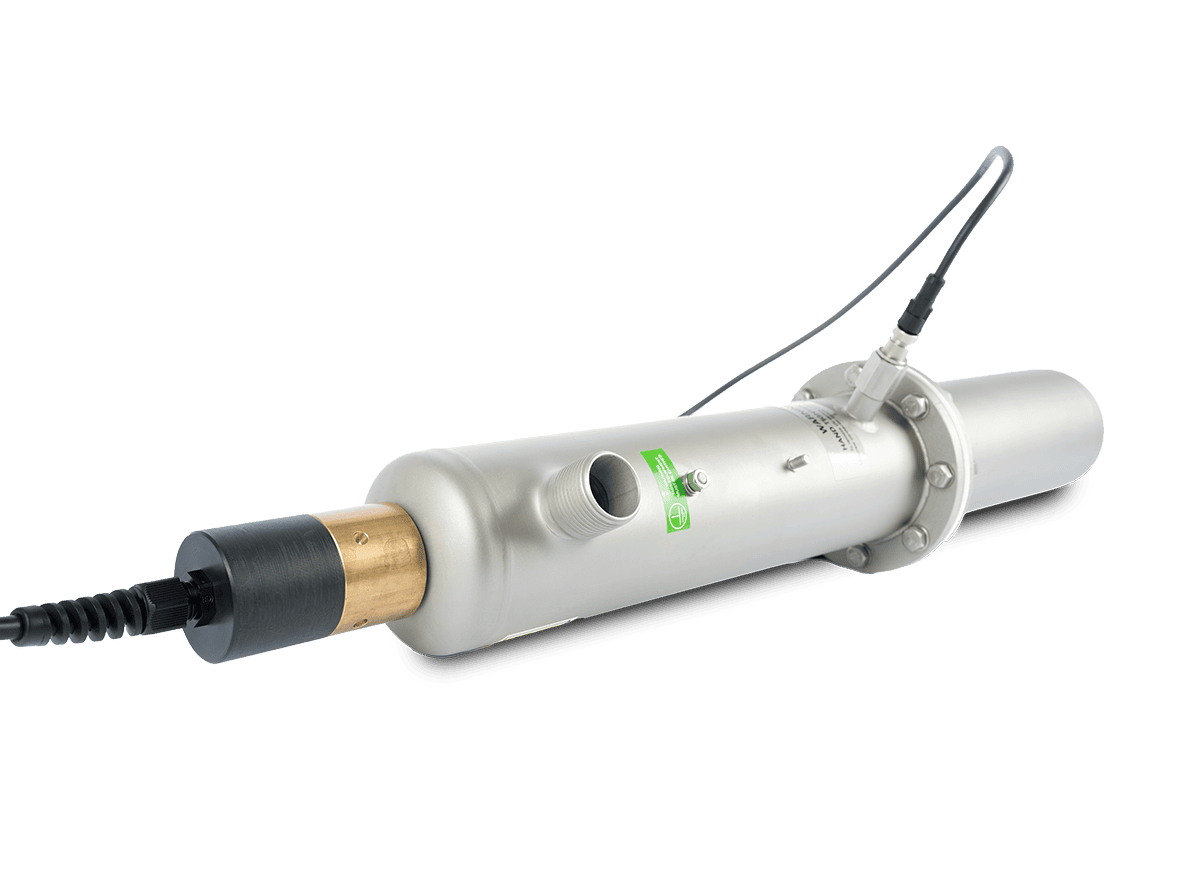

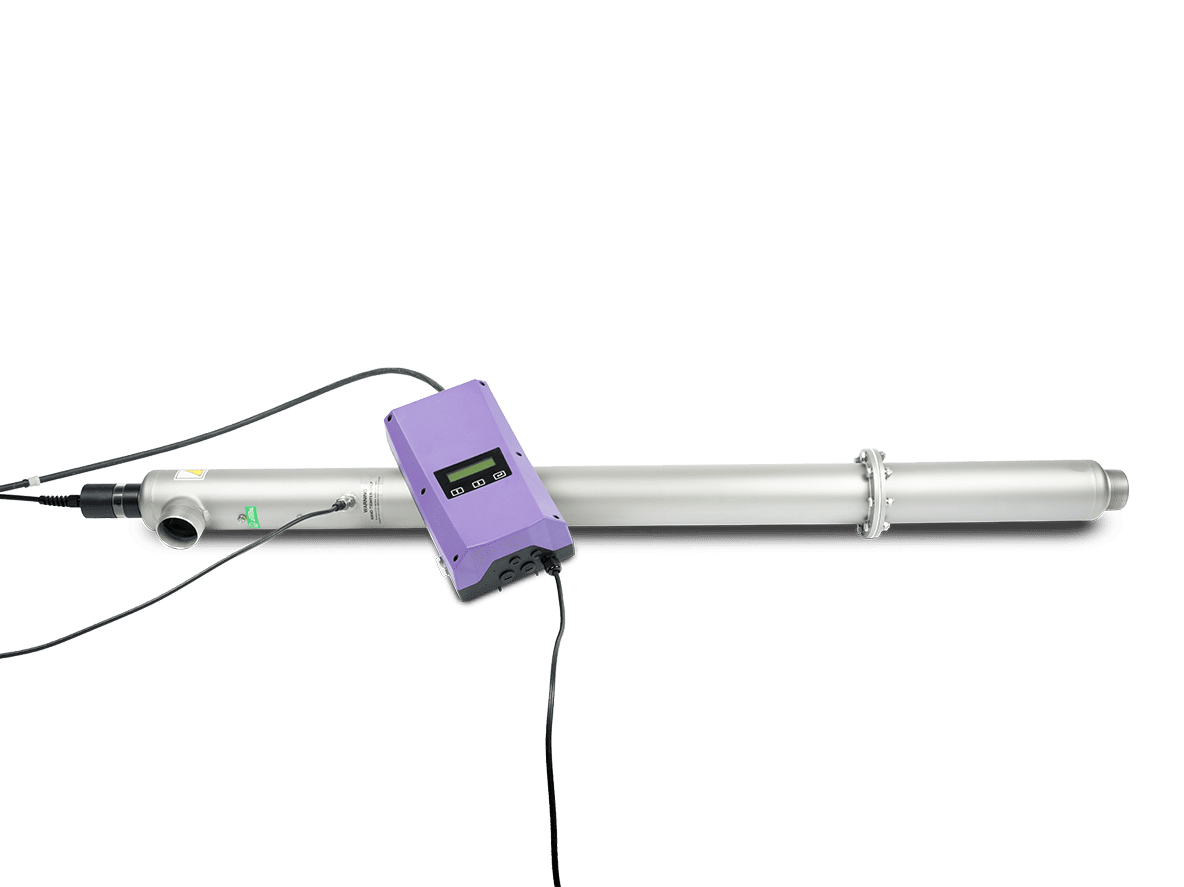

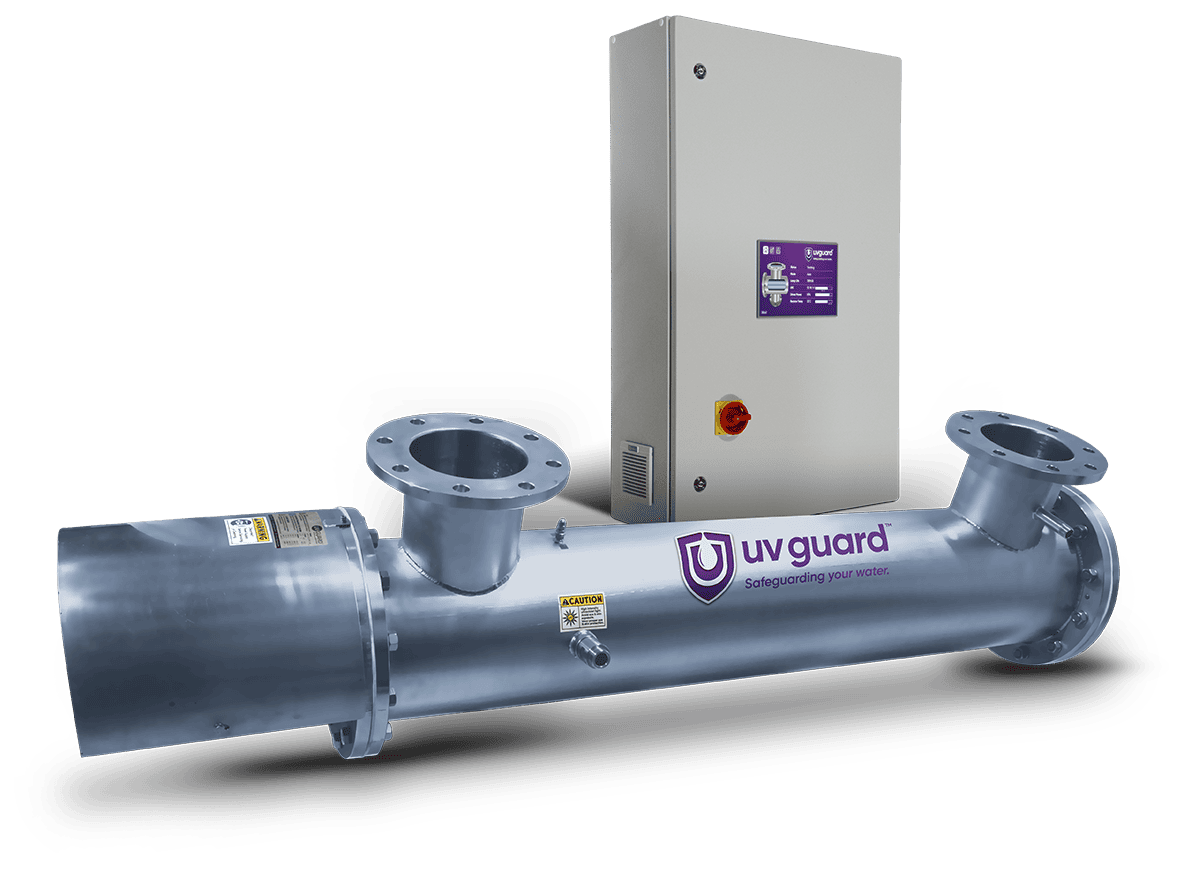

UV Guard offers a wide range of systems suitable for food-grade applications, including the MPX-Series, Guardian, and S-Series. For larger operations, see our Commercial Water Treatment Systems. For domestic or smaller-scale use, view our Residential Water Treatment. Or explore all UV disinfection system applications.

Food & Beverage Applications

UV Guard disinfection systems can be used in any production process where there is a need for clean, microbial free and safe water. This includes:

- Maintain hygienic bottle rinsing by treating rinse water with food and beverage UV water treatment.

- Protect stored water in tank headspaces from airborne microbial contamination.

- Treat inlet and outlet connections for tanks to reduce contamination risks at critical control points.

- Disinfect ingredient fluids such as sugar syrup or other raw liquid components used in production.

- Control microbes in cooling fluids, reducing the risk of biofilm and spoilage.

- Support yeast preparation processes by removing unwanted organisms that may affect performance or flavour.

Related Products

Case Studies

See how UV Guard has helped food processors and beverage manufacturers maintain water purity, prevent contamination and meet safety standards with UV water treatment for food and beverage industries. Our case studies show real-world examples where food and beverage UV water treatment improved process reliability and reduced product losses.

Coca Cola – Sugar syrup (liquid sugar) UV treatment

Coca Cola is a major manufacturer of beverages including soft drinks, bottled water, sports drinks and fruit juices. Coca Cola in Richlands Queensland was installing a new production line which required Ultraviolet (UV) disinfection for the sugar syrup application. The UV system on the existing production line also required an upgrade.

Tropical Ice – process water UV disinfection for ice manufacturing

Tropical Ice are an ice producer who supply over 110 tonnes of ice to their customers each day. Tropical Ice is one of the largest producers of high quality, food-grade ice in Australia. The water they use must meet all required Australian health regulations.

Freshwater Systems Australia Case Study – UV Guard

Discover how Freshwater Systems Australia and UV Guard's strategic partnership drives success in delivering water treatment solutions across healthcare, pharmaceutical, and domestic industries. Learn about our collective technical expertise, and commitment to meeting stringent water quality guidelines.

Frequently Asked Questions (FAQ)

Get in touch

Contact our team to discuss the right UV water treatment solution for your food and beverage operations.

Newsletter

Stay up-to-date with our very latest news, technology, offers and events.